Subscribe To Our Weekly Newsletter

Categories

An update from Hamish Ross on ehancing Precision Agriculture with John Deere tech tools of the trade

The past quarter has been a whirlwind of activity for the TECSight team, with our focus squarely on supporting our customers across New South Wales and enhancing precision agriculture. We’ve handled 3675 calls, ensuring that our customers receive the best possible service and support in their precision agriculture endeavours.

For the Precision Ag team, it’s been clinics, clinics, and more

clinics. From Albury to Wagga Wagga, Wee Waa, Gunnedah,

and Quirindi, our team has been on the road, sharing the latest

in precision ag technology. We’ve also had a strong presence

at AGQuip Field Days and assisted to conduct a nitrogen

trial at CSU (led by Incitec Pivot), showcasing the real-world

application of available solutions. If you haven’t been invited

to a clinic in your locality, please reach out to your local branch

and we will get one organised!

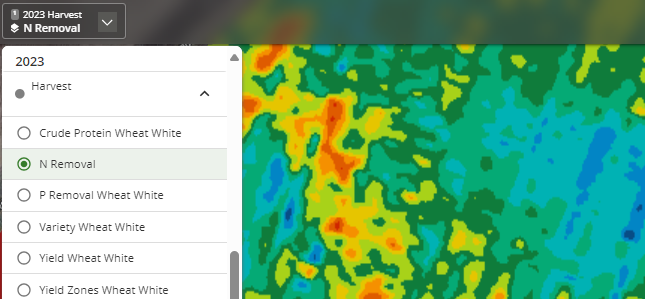

One of the key areas we’ve been working on is protein analysis with the HarvestLab™ 3000. This advanced tool, which can be

installed on S700 combines (soon to be available on X Series Combines!), allows for the real-time recording of protein, moisture and oil content in canola, as well as protein, starch and moisture levels in barley and wheat. Our partnership

with PCT Agcloud, world leader precision ag software, has been pivotal in this space. Protein Pro, a solution developed

by PCT AgCloud and available exclusively through the John Deere Dealer network, enables growers to precisely assess how management practices, agronomic factors, and crop varieties influence the quality of their yield. As dealers for PCT

software, we’re excited to offer an online tool that automates the collection and analysis of protein data. If you’re using any brand of protein analyser on your machine, we recommend calling us to discuss what value could be unlocked by utilising PCT Protein Pro. The process is fully automated and cleans and edits multiple machine corrections. It also creates N removal maps and product replacement maps when soiuld test data is available. All seamlessly visible in Operations Center with prescriptons wirlelessly sent to the machine if JDLink available.

The benefits are substantial:

- Quickly create a Nitrogen or any other nutrient

application map. - Combine and monitor with in season imagery for in

crop top up. - Manage protein and yield to optimize yield to match

land capability. - Investigate variability in protein and yield with

landscape and soil type. - NPK removal from bushels

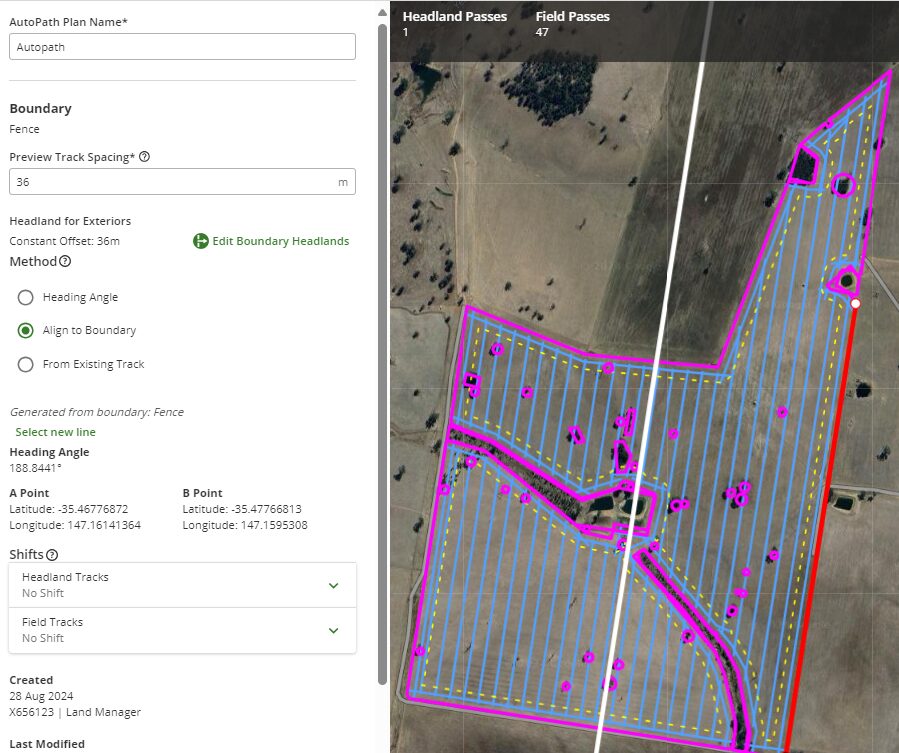

Another significant focus has been converting competitive

guidance lines and boundaries over to John Deere, along with

integrating SF-RTK lines. With the recent addition of guidance

line converter located in Operations Center, this is made

extremely simple. If your Operations Center is in need of a

tidy up or you have non John Deere systems, please reach

out to TECSight or the PA team and we can visit you or assist

remotely. In June, we unlocked AutoPath™ from boundary, a

game-changer for our customers. AutoPath from boundary

is a guidance system that uses data from the boundary

information to create the most efficient way to cover the

paddock. Available as part of the Automation 4.0 Package.

AutoPath™ simplifies field operations by creating a single

guidance track per field, leading to a more efficient way to

complete tasks. The feedback has been overwhelmingly

positive, and we’re excited about the impact this will have on

our customers’ productivity.

We also recently introduced the Agronomy Analyser tool,

which has already proven to be an invaluable asset for our

customers. This tool assists in creating trials and variable

rate prescription maps with ease. We completed a trial at

CSU with Incitec Pivot, focusing on liquid versus dry fertilizer

applications. This trial demonstrated how seamlessly the John

Deere tech suite can be used to create prescriptions, conduct

trials, and send data directly to the machine. The result was

a broad-scale trial that was straightforward to administer,

highlighting the user-friendly nature of our technology

OTHER KEY UPDATES:

In addition to AutoPath™ (Boundaries), here are some recent enhancements in the John Deere Operations Center:

- Turn Size Adjustments for AutoTrac™: Operators can now make precise turn adjustments using a fixed scale for

better control - Skip Turn Recommendations: The latest update (24-1) offers automated suggestions to improve turn quality,

optimizing spacing and headland size - Idle Reasons: Gen 4 and G5 users can now log ‘idle reasons’ in-cab, helping identify operational inefficiencies.

- In-Field Data Sharing: Several updates have been made to improve the overall data-sharing experience in the field

To stay ahead of the curve and make the most out of the advancements, contact Precision Ag on 0488 885 667

Articles And Resources From The Hutcheon & Pearce Newsroom

The 101 on Precision Essentials

John Deere’s exciting new Precision Ag model – Precision Essentials-

John Deere Seeding: Smarter Together

Experience precision, productivity and peace of mind with a complete

Celebrating Success: H&P Apprenticeship Graduation

Hutcheon & Pearce celebrate their newest graduates of the High

Cobram Women in Turf Program a Success

An action-packed week at the Cobram Barooga Golf Club saw