Subscribe To Our Weekly Newsletter

Categories

Integrated Solution Manager, Hamish Ross, shares an update on Precision Ags Harvest activities

The past quarter has been a busy one for the TECSight team as Harvest ramped up. Our primary focus was on supporting our customers to get in and get it done as efficiently as possible. Over the quarter 5,584 calls to TECSight were handled as our team went above and beyond to ensure our customers received the best support during the harvest period.

Harvest also took centre stage for our Precision Ag team, with a series of exciting harvester demos held across NSW. Our team showcased the new John Deere X9110 and S7900 at various customer locations, sharing the latest technological innovations set to revolutionise harvesting.

We are currently assisting in a Harvest trial at CSU and will also be harvesting the Oaklands Football Club paddock to ensure we can get as many people to view the new combines as we possibly can.

As we get closer to fully autonomous operations, we’re continuing to help farmers prepare by assisting in the adoption of precision agriculture features and following key updates.

X9100 and s7 Demos:

In late October one of our Precision Ag team members and one of our salesmen went up to North Star, where John Deere introduced the all-new X9100 and S7 harvesters and held training sessions. Our team had an invaluable couple of days, taking away extensive knowledge of the products ready to share with the rest of the H&P team and our customers.

These new combine models feature the latest autonomous capabilities, including harvest automation, machine sync and predictive ground speed automation, which are exciting features enhancing the accuracy and productivity of harvest operations.

Following the team’s training with John Deere, we organised several demos to be held on customer farms across NSW. From Wee Waa to Narromine and Forbes to Temora, we tried to get a wide coverage across the state, allowing interested farmers to check out and experience firsthand these state-of-the-art harvesters. We held five demos for each machine, and not only did we receive some really positive feedback from customers, but we also got some successful data which speaks for itself.

Harvest Automation Reports

John Deere have praised these machines for providing a 20% improvement in productivity when utilising full harvest automation and have released data reports post demos which fully support these claims.

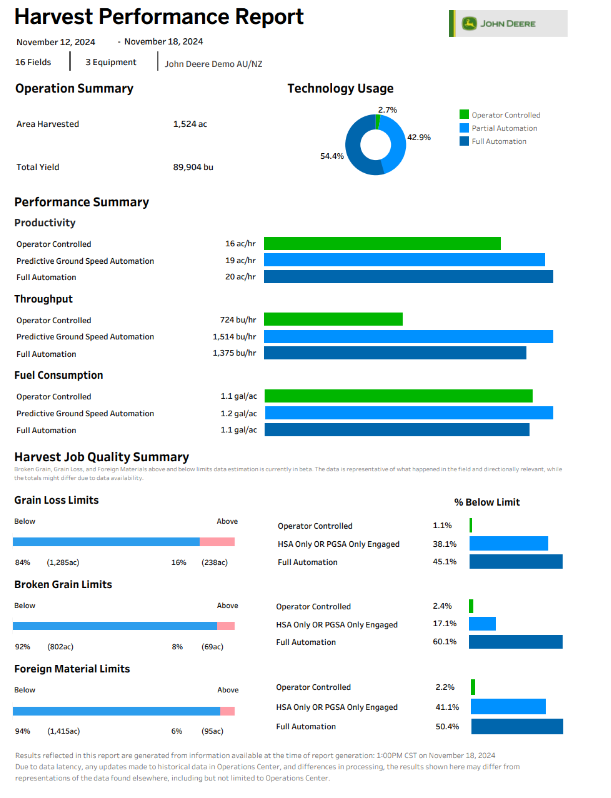

These harvest automation reports, which you can see in figure 1, are from the John Deere demonstration account which includes the entire John Deere demo setup in Australia.

From the week of November 12 to November 18, across 16 fields and three pieces of equipment, a significant productivity increase is noticed between operator-controlled and full automation in machines. Operator control was achieving an average of 16 ac/hr, predictive ground speed automation increased this to 19 ac/hr, and full automation achieved the highest productivity at 20 ac/hr.

Furthermore, we can see that the throughput for predictive ground speed automation and full automation are both double that of operator-controlled settings. This is significant to consider when looking at the fuel consumption as whilst the gal/ac are similar across the board, the throughput is not and therefore the predictive ground speed and full automation are much more fuel efficient for what they are achieving.

After these demos we have had several customers keen to get their hands on the new combines which is great feedback. We now look forward to assisting with the Charles Sturt University trial, where we will be harvesting one paddock with the new S7 and its harvest automation features.

Protein Analysis

In our last edition, we spoke about how we had been working on protein analysis with the HarvestLab 3000 and how our partnership with PCT Ag cloud has been pivotal, providing the PTC Protein Pro which enables growers to precisely assess their grain quality.

The HarvestLab 3000 has been available for over three years on the S700 and has recently been released on some X9 models. We are really looking forward to analysing the PCT Protein Pro data after harvest is complete and getting some yield maps together. This data is highly valuable to growers and can be used to create yield zones

If you are currently using a protein analyser on your machine or interested in using one, we couldn’t recommend the PCT Protein Pro any higher. It is available exclusively through John Deere dealers, so contact Precision Ag on 0488 885 667 to discuss the value you could unlock.

Articles And Resources From The Hutcheon & Pearce Newsroom

John Deere Seeding: Smarter Together

Experience precision, productivity and peace of mind with a complete

Celebrating Success: H&P Apprenticeship Graduation

Hutcheon & Pearce celebrate their newest graduates of the High

Cobram Women in Turf Program a Success

An action-packed week at the Cobram Barooga Golf Club saw