7400A TerrainCut™

Trim, Rough & Surrounds Mower

- TechControl Display locks in performance, and uptime

- LoadMatch™ to maintain cut quality

- 35% larger traction drive, 17% larger wheel motor displacement

Features

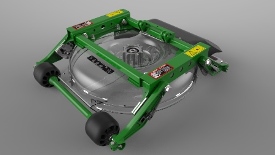

Stamped rotary decks and rigid frame construction to maximize deck durability

9009A TerrainCut™ Rough Mower

9009A TerrainCut™ Rough Mower

7400A TerrainCut Trim and Surrounds Mower

7400A TerrainCut Trim and Surrounds Mower

The 9009A TerrainCut Rough Mower is equipped with five and the 7400A TerrainCut Trim and Surrounds mower is equipped with three 27-in. (68.6-cm) stamped rotary decks for superior productivity and strength. The rotary decks perform exceptionally well across a wide range of grass types, including warm- and cool-season grasses.

Stamped deck shell

Stamped deck shell

A strong stamped, 10-gauge shell construction is an integral part of this durable deck. The stamped design uses a single piece of steel to form the shell that provides consistent strength throughout all areas of the deck. This is the starting point of the strength and durability of the deck construction.

Frame support and protection

Frame support and protection

Surrounding the deck is a tough, steel frame designed to protect the deck shell. It all starts with the frame on top of the deck which is then bolted to the shell providing extra protection. The front and rear roller brackets are attached to the framework, so as the front and rear rollers encounter obstacles, the force is transferred through the frame rather than through the deck shell. This design also decreases the distance from the blade tip to outside edge of the deck for closer trimming around objects like trees and fences.

An angled skid plate between the front roller and deck shell helps protect the front lip of the deck from tough terrain such as tree roots or other objects. The skid plate helps move the deck over the object to prevent the front edge from contacting and damaging the deck shell. The side of the deck also has additional protection to increase durability with a 1.5-in. (38-mm) tall and 0.5-in. (12.7-mm) thick steel stock welded to the decks edge.

Roller brackets are cast steel with extended housings to effectively protect the roller bearings from a wide range of debris types. The large front rollers are greaseable to help purge water and debris and use snap rings to ensure bearings stay in place, increasing durability and longevity of the front rollers.

Rear-discharge design provides premium cut quality and dispersal for less clumping and blowing for clean up

27-in. (68.6-cm) deck and frame

27-in. (68.6-cm) deck and frame

Asymmetric rear discharge

Asymmetric rear discharge

The 9009A and 7400A TerrainCut™ Mowers 27-in. (68.6-cm) deck features a deck design with an asymmetric rear discharge cutout and molded chute to promote better airflow, leading to improved clipping dispersal and cut quality.

The unique shape of the deck shell cutout includes a heavily rounded opening on one side that gradually transitions to a larger opening on the other side of the cutout, allowing the grass to exit the deck evenly while significantly reducing the possibility of the deck congestion. This design incorporates deck structure along the bottom of the discharge area that reduces sound power, does not affect cut quality negatively, and acts as a foot guard eliminating the need for an external guard that can lead to external grass build up which can be dropped in the mowing pass over time.

When the asymmetric deck shell discharge shape is used in combination with the asymmetric discharge chute, this deck outperforms the competition in cut quality by minimizing clumping with smooth transitions and guiding the discharge material in a more dispersed pattern.

The improved dispersal will lead to less clean up and blowing, allowing machines to mow earlier in the day while saving time and reducing labor.

The proper blade selection for heights of grass, grass type, and sharp blades are keys to improved cut quality and dispersal. The removal of no more than one third of the grass blade is recommended. During heavy growth times it may require changing blades, mowing more often or raising the height of cut to improve clipping dispersal.

No-tool notch adjustment system makes height-of-cut (HOC) changes a breeze

Deck HOC system

Deck HOC system

One common element among John Deere golf mowing products, reel or rotary, is that adjustments are quick and easy. The 9009A and 7400A TerrainCut™ Mowers are no different. All HOC adjustments can be performed without tools with an innovative notch system, similar to what is included on the Quick-Adjust 5 and Quick-Adjust 7 reel cutting units.

To adjust the HOC on the 9009A and 7400A TerrainCut, pull the levers at each end of the front and rear rollers outward. With the levers pulled out, give a quick tug to disengage the teeth in the notches. This allows the rollers to rotate upward and downward freely and easily.

Inside HOC indicator

Inside HOC indicator

Outside HOC indicator

Outside HOC indicator

Locate the HOC indicator on the inside of the adjuster arm and line up the tabs or use the top edge of the adjuster arm to line up the height on the gauge located on the outside. Re-engage the notches by rotating the levers back inward to lock the HOC into place. No tools are needed to complete the adjustment.

The adjustments must be performed on both the front and rear roller, and both rollers have the same adjustment process. A HOC label is also located on the rear of the deck to serve as a guide for setting the height of cut.

The HOC is adjustable 3/4 in. (1.9 cm) to 4 in. (10.2 cm), in 1/4-in. (0.64-cm) increments.

The HOC system has been redesigned from prior models to include a longer and stronger handle. Hardened notch material is used to improve durability and resistance to rust and debris.

Powerful turbocharged diesel engine offers the highest horsepower in its class

Overall engine view from left side of machine

Overall engine view from left side of machine

Power starts with the engine, and the 7400A TerrainCut™ Trim and Surrounds Mower has an abundance of power and performance. The 37.1-hp* (27.7-kW) at 2600 rpm turbocharged diesel engine is the same engine used in the PrecisionCut™ and E-Cut™ Hybrid Fairway Mowers that has a strong reputation for power and performance.

The 7400A TerrainCut Trim and Surrounds Mower offers the highest horsepower rating in its class. This is important because this powerful engine combination provides plenty of reserve power for climbing hills, without sacrificing power to run the 27-in. (68.6-cm) rotary decks in lush and thick grasses.

The air-intake system is also designed to pull clean air from the front of the machine behind the operator's seat, rather than dirty air from the rear of the machine. This improves engine performance and efficiency.

*Engine horsepower and torque information are provided by the engine manufacturer to be used for comparison purposes only. Actual operating horsepower and torque will be less. Refer to the engine manufacturer’s website for additional information.

TechControl display maximizes performance and uptime by allowing more control in operation and diagnostics

TechControl display

TechControl display

Password-protected settings

Password-protected settings

More control with the TechControl display with a large easy-to-read screen

Passcode-protected TechControl display enables quickly setting or changing mowing speed, turning speed, or transport speed to limit variations in performance by different operators.

Mow setting screen

Mow setting screen

Quickly adjust the mow or transport speed to make sure mow speed is what is needed for the changing conditions. The setting can be adjusted precisely using a speedometer app on a smartphone or GPS device.

Turn-speed setting screen

Turn-speed setting screen

Use the TechControl to slow the machine during turns while mowing and protect against turf scuffing and aggressive turning operators.

The turn speed control engages when in mow and the cutting units are lifted for turns. Once the turn is made and the cutting units are lowered, the machine speed returns to the set mow speed.

The turn speed is a percentage of mow speed. When set to 100 percent, turn speed control is off or allows 100 percent of the mow speed in turns. Turn speed setting of 50 percent allows only 50 percent of the set mow speed to be reached during turns.

Here is an example:

Mow speed = 6 mph (9.66 km/h)

Turn speed set at 50 percent

Maximum turning speed will be 3 mph (4.83 km/h)

Input/output screen

Input/output screen

Service timers screen

Service timers screen

The A-model PrecisionCut™ Mowers, E-Cut™ Hybrid Mowers, and TerrainCut™ Mowers have the latest in advanced diagnostics through the TechControl display. Most all diagnostics are performed while sitting in the operator’s seat.

The TechControl has onboard visual diagnostics allowing quick and easy machine diagnostics, maximizing up time. The system allows technician to see inputs and outputs of the electrical system. Also, the technician can see stored controller codes on the machine to aide in troubleshooting incidents that may have occurred while on the course.

The TechControl will also display the notification for maintenance of the hydraulic and engine oils using service timers to notify when it has reached the time to perform the required service.

Language settings

Language settings

Choose from a list of several languages to use for the TechControl.

Operator warning notifications are incorporated into the TechControl and will alert the operator if a problem arises during operation.

Description |

Hydraulic over temp |

Hydraulic oil filter restriction |

Engine oil pressure low |

Engine coolant temperature |

Reel motor |

Battery voltage |

eHydro™ hydrostatic pump and large-capacity wheel motors for serious hill-climbing capabilities

Large wheel motors

Large wheel motors

eHydro™

eHydro™

The eHydro™ traction pump and wheel motors in the new A-model take performance, traction, and operation to the next level.

The new system was designed to take on the most challenging course conditions. The traction drive pump flow increased 35 percent and the wheel motors increase 17 percent in displacement over prior models. These increases to the traction system makes the A-models ideal for undulating terrain providing superior performance and traction out on the course.

The new traction system in the A-models is driven by a servo-controlled hydrostatic pump. The control of the pump is no longer mechanical linkages, but instead is electronic.

Approximately 110 parts have been eliminated from the traction drive system compared to prior models. The new design also eliminated two adjustments. Reducing the complexity of the drive system means no more linkages to adjust or repair, decreased routine maintenance, and providing reliable day-in/day-out operation.

Forward/reverse pedals

Forward/reverse pedals

The operator will like the eHydro, too. The pedal effort has been reduced, thus reducing the foot fatigue during many hours of mowing.

LoadMatch™ electronic setting compensates speed of machine to keep power to the cutting units to maintain cut quality

LoadMatch setting

LoadMatch setting

LoadMatch is an electronic setting through the TechControl display that allows managers more control of the machine and how it is operated when out on the course.

Most operators will mow as fast as the mow setting will allow, keeping their traction pedal all the way down. However, in some conditions this can lead to poor cut quality.

One example is getting behind in mowing due to weather conditions. The grass is long and lush and to properly cut that amount of grass at one time, the operator should slow the traction speed. This allows the cutting units to maintain proper turning speed, process the grass, and properly cut in one pass. Not slowing down causes missed grass and an uneven appearance. This affects the after-cut appearance and also reduces productivity by having to mow a second time to properly cut the lush grass.

The LoadMatch feature compensates the traction speed of machine to keep power to the cutting units. In the long, lush conditions described above with LoadMatch engaged, the operator would still have the traction pedal all the way down, but the machines would sense the load and slow the traction speed to properly cut the mowing pass. Once the load is reduced, the machine will return to the normal mow speed.

LoadMatch puts the manager in control of cut quality, instead of the operator.

Width on demand—match the conditions with the touch of a button

Featuring both a 68-in. (172.7-cm) and 74-in. (188-cm) width of cut that can be changed with the touch of a button, the 7400A Trim and Surrounds Mower ensures that all grass in its path is cut in both flat and undulating conditions.

The narrower width of cut is recommended for undulating terrain and tight turns where more cutting overlap is required, to make sure that no uncut grass is left behind. This width expands the total cutting unit overlap to maximize cut quality by eliminating uncut strips of grass that may be caused by undulating terrain, or a layout that requires a lot of tight turns.

This exclusive feature provides a productivity boost compared to competitive equipment in the marketplace. The wider width of cut setting is recommended on flat terrain with long straight runs. This width of cut has maximum productivity with minimal overlap.

Deck-shifting mechanism

Deck-shifting mechanism

Front decks shift for productivity

Front decks shift for productivity

Where some machines in the marketplace have to completely replace lift arms to change from a 68-in. (172.7-cm) width of cut to a 72-in. (182.9-cm) width of cut, the 7400A Mower allows changes to be made from the seat by hydraulically shifting the front decks in our out, with no additional parts to purchase. All it takes is the touch of a button.

Operator selects width of cut

Operator selects width of cut

Changing width of cut with the width-on-demand system is simple, and can be done while the decks are on the ground or raised. Simply toggle the width-on-demand switch on the operator command arm to spread the decks wider to the 74-in. (188-cm) width of cut, or toggle to bring the decks into the tighter 68-in. (172.7-cm) mowing width.

This maximizes productivity by offering a choice of the width that best suits the terrain. And the terrain may allow for both modes in different areas. For example, the 68-in. (172.7-cm) width may be used in mounding areas or areas around bunkers, but once the terrain flattens out and the extra overlap is not needed, it can be switched to the 74-in. (188-cm) width. The 74-in. (188-cm) width boosts productivity by 9 percent compared to the 68-in. (172.7-cm) width of cut.

How a golf course uses the system is up to the golf course. There are areas on the golf course where each width may come in handy to maximize productivity to get the job done faster, and with excellent cut quality.

Reach Trimming System—shift out to trim around bunkers and other hard-to-reach places

Right deck fully extended for bunker trimming

Right deck fully extended for bunker trimming

Having difficulty trimming around bunkers? The 7400A TerrainCut™ Trim and Surrounds Mower is here to help. Featuring an industry-exclusive Reach Trimming System, the 7400A Mower reaches out to bunkers and trims around them with ease.

With the Reach Trimming System, one of the front decks can be shifted outward to extend the deck 15 in. (38.10 cm) beyond the outer edge of the tire for trimming. Shifting only one deck helps keep the machine's center of gravity more consistent, maintaining the machine's overall stability.

It is recommended to mow the outer areas around the bunker or other areas to be trimmed first, and then use the Reach Trimming System as the last pass against the area to be trimmed.

Operating the Reach Trimming System is done with ease. It is very similar to adjusting the mirrors in a car. To adjust the mirrors, there is a switch to select which mirror to adjust and another switch to adjust the direction the mirror is moved.

Operator selects deck to extend for trimming

Operator selects deck to extend for trimming

Operator extends deck for trimming

Operator extends deck for trimming

To use the Reach Trimming System, toggle the select switch left to select the front left deck or right to select the right front deck. The select switch is the one with the yellow decals on the switch.

Then, press the extend/retract switch to the left to extend the left deck outward or to the right to extend the right deck outward. The longer the switch is held, the farther the deck extends until it reaches its farthest position 15 in. (38.10 cm) beyond the outer edge of the tire. The system is now set up to trim around the bunker or other trimming area.

Retract the decks by simply returning the mode-select switch to its middle position, or by pulling back on the lift/lower handle to raise the decks and automatically return them to their neutral position.

The Reach Trimming System increases productivity by allowing more access to those hard-to-reach places, but does so without compromising the machine's overall stability by only extending one deck outward for trimming.

GRIP All-Wheel Drive Traction System moves flow from wheels that slip to those that grip

Hill-climbing power is essential with any golf course mower, and this is one area where the A-model PrecisionCut™ and TerrainCut™ Trim and Surrounds Mowers truly excel. A powerful diesel engine supplies power to the system. Combine that with a new larger eHydro™ and wheel motors the GRIP all-wheel drive traction system, and the A-Model is one powerful hill-climbing machine. The new traction drive delivers 35 percent more flow from the hydrostatic pump and 17 percent more wheel torque than previous models to deliver the hill-climbing performance expected with a trim and surrounds mower.

The GRIP system transfers hydraulic flow from wheels that slip to wheels that grip. For example, if the right front wheel starts to slip, hydraulic flow goes to the left front and rear tires to maintain traction power.

The GRIP all-wheel drive traction system is standard equipment with the A-Model Trim and Surrounds Mower. It is also engaged at all times, in mow or in transport.

7400A TerrainCut™