6100E

Tractor

- PowerTech™ E (Tier 3) 4.5L (276 cu in.)

- Category 2, 3-point hitch

- MFWD / 2WD

- Open station / cab

Features

6E Series Tractors name and numbering

The tractor model numbers are comprised of four positions. The first number designates the family while the next three numbers represent the approximate engine horsepower. The fifth and sixth positions are represented by a letter. The first letter indicates the level of capability or price a tractor has. Not every tractor will have a second letter. But if it does, the second letter represents a special configuration of the tractor.

The size of the tractor is how large the tractor is compared to other tractors John Deere offers, using the similar sizes of today's product groupings and still sustaining the tradition of the name and numbering legacy. These are referred to as Six Series Tractors. This name and numbering system will not change that. The 6E is similar in size to the 6003 Series.

The second position is the tractor's approximate engine power. The 6100E at 99 hp, 6115E at 118 hp, and 6130E at 130 hp have been rounded to the nearest 5 hp. John Deere has promoted PTO horsepower for its utility and row-crop tractors and engine horsepower for its four-wheel drive (4WD) tractors. This has led to some confusion in the marketplace. Although promoting PTO horsepower has its benefits, using bare-engine horsepower allows for a more consistent means of promoting tractor horsepower in a global market.

Bare-engine horsepower is measured by running just the bare block engine with the front fan. With bare engine horsepower, John Deere is using the International Organization for Standardization (ISO) 97/68 E-C standard for determining the bare-engine horsepower at rated engine speed, given in metric horsepower, not Society of Automotive Engineers (SAE). This unit of measurement is used globally to describe off-road engines. This will allow John Deere to consistently promote the tractor's approximate horsepower within the model number across all tractors around the world.

The third position is the tractor's capability or price level within its family. In general terms, capability is the specification level of that tractor series, such as the type of engine, transmission, frame, and overall design; all leading to price. The letter D would equal a very basic tractor; M would signify a premium tractor, while the letter R would equal a very premium tractor with many options and features. The higher the letter is in the alphabet the higher the tractor's spec level. If the tractor has a second letter, the second letter represents the configuration of the tractor. For example, H will designate high-crop and V will designate a vineyard design.

Another important part of the name and number system is the way that these tractor models are pronounced. The former system would have said sixty-one-forty-E, but since the second, third, and fourth positions are the engine horsepower and not part of the tractor's size, the numbers need to be separated.

The correct way to say this tractor lineup is:

- 6100E: six-one-hundred-E

- 6115E: six-one-fifteen-E

- 6130E: six-one-thirty-E

This is a significant change to what has been used in the past, but the value and the solutions of these tractors remain the same.

Precision Ag Technology options available

AutoTrac™ automatic guidance system

AutoTrac™ automatic guidance system

The 6E Series Cab Tractors can be equipped (factory installed) with AutoTrac automatic guidance system, available in the following configuration: AutoTrac Universal.

The AutoTrac system can greatly reduce a producer’s costs by eliminating over pass, providing great economy in fuel consumption, and improving the efficiency of many other inputs such as fertilizers, seeds, and chemicals. It allows the adoption of precision agriculture systems, such as variable rate, controlled traffic, etc.

John Deere value benefits

4640 Universal Display

4640 Universal Display

4240 Universal Display

4240 Universal Display

AutoTrac Universal 300

AutoTrac Universal 300

John Deere value benefits:

- Large reduction in supply and fuel costs

- Increased efficiency in area usage

- Excellent for nighttime operations

- Facilitates operator’s work

- Alignment with all ag operations such as tillage, planting, spraying, and harvesting, allowing reduction in losses during harvest and crop care operations

Features and benefits profile

John Deere diesel engines

- Tier 3 engine available in the 6100E, 6115E, and 6130E.

- 4-cylinder 4.5L PowerTech™ E engine turbocharged intercooled for 6100E, 6115E, and 6130E models.

- Under-hood muffler allows for reduced sound levels, a clean hood profile, and excellent visibility.

Transmissions

- Four 30K transmissions available to match producers’ needs:

- Twelve forward/ four reverse (12F/4R) top shaft synchronized (TSS) with wet clutch

- 24F/8R TSS Hi-Lo with wet clutch

- 12F/12R PowrReverser™ wet clutch

- 24F/12R PowrReverser Plus wet clutch

- Special 40K transmission to work faster available in:

- 24F/12R PowrReverser Plus wet clutch

Heavy-duty two-wheel drive (2WD) front axle

- The two-wheel drive (2WD) front axle is manufactured from heavy-duty nodular cast iron for superior strength and durability and is available in the 6100E and 6115E.

Mechanical front-wheel drive (MFWD) (optional)

- The caster action front-wheel drive design permits wheels to tilt and tuck under tractor chassis to achieve sharp turns. It improves stability and steering accuracy and provides positive turn traction and allows a maximum 52-degree turn angle.

- Inboard planetary final drives

- Distributes axle load equally over three points. Reduces stress on individual gears and shafts for increased reliability

Hydrostatic power steering

- Hydrostatic steering provides optimum performance and efficiency in all operating conditions with minimal effort.

Open-center hydraulic system

- All 6E Series Tractors feature a gear-driven, open-center (constant-flow) hydraulic system with a maximum pressure of 19,500 kPa (2830 psi), with a rated flow to the rear selective control valves (SCVs) of 73.2 L/min (19.1 gpm).

Joystick control lever

- Optional mid-mount valve with joystick allows multiple functions to be performed by one lever, which is especially useful for loader operations.

Category 2, 3-point hitch

- Features a rugged, Category 2, 3-point hitch designed to SAE standards, to accommodate demanding implement draft and lift requirements, plus a Category 2 drawbar to tackle the toughest drawbar loads

Top adjustable swinging drawbar

- Equipped with an in-base Category 2 swinging drawbar, which allows the operator to slide the drawbar to one side for power take-off (PTO) operations, especially useful with hay equipment

- Independent 540/1000 rpm PTO

- Easily switch between 540 and 1000 rpm-driven implements simply by removing the stub shaft and reversing its position

Mechanically actuated wet-disk brakes

- Smooth braking

- Longer life

Differential lock

- Maximizes traction

Operator’s station

- Both cab and open operator station (OOS) platforms offer easy, uncluttered access to all tractor and implement controls.

- The controls are ergonomically located and color coded, giving the operator natural and logical command of all functions.

Fixed or foldable Roll-Gard™ rollover protective structure (ROPS)

- The foldable Roll-Gard can be adjusted from the seat. The tractor will fit under standard 203.2-cm (80-in.) door openings. The tractor’s height with fixed ROPS is around 254 cm (100 in.), depending on the wheel size.

Factory-installed cab

- A ROPS-certified, factory-installed cab is available to all operators. The cab provides protection from heat and cold, wind, noise, and offers a climate-controlled environment. The cabs are also assembled to the tractor chassis as a complete unit mounted on composite isolators.

Standard seat for open operator station (OOS) tractors and deluxe seat for cabs

- Vinyl standard seats are fully adjustable fore/aft and weight. A factory-installed armrest option is available. Deluxe seats used in cabs are fully adjustable fore/aft along with height and weight. Seats are equipped with a seat switch to detect operator’s presence for the PTO alarm. Both kinds of seats have retractable seat belts.

Composite fenders and hood

- Resists paint chips and dents

- Will not rust and retains a like-new finish longer

- Hood tilts up to provide easy access for service.

Cab platform

Cab interior

Cab interior

A rollover protective structure (ROPS)-certified, factory-installed cab is available to all operators. The cab provides protection from heat and cold, wind, noise, and offers a climate-controlled environment. The cabs are also assembled to the tractor chassis as a complete unit mounted on composite isolators.

AutoTrac™ Universal ready

John Deere 6E Series Cab Tractors equipped with the GreenStar ready wiring harness are easily compatible with John Deere precision agricultural products. AutoTrac Universal ready includes:

- GreenStar display bracket and an A-post connector

- StarFire™ receiver bracket and connector

- AutoTrac Universal 300, StarFire 6000 Receiver, and Gen 4 wiring harness installed on the tractor

Fully isolated cab advantages

By including the floor and steering column as part of the cab, it significantly reduces noise levels in the cab. It also creates a more sealed environment by reducing airborne particles entering the cab, such as dust, pollen, and other contaminants. The 6E Series Cab Tractors are base equipped with a mechanical cloth seat for standard comfort. For those who will be operating on rough or unstable terrain, an optional air suspension seat is available that gives maximum comfort.

Air suspension seat

Air suspension seat

The cab is incredibly spacious, and the flat floor creates a spacious feel. The operator of a 6E Series Cab Tractor will appreciate the reduction in noise and vibration through the seat, steering wheel, and lever controls. By adding the cab to the tractor, the noise level is decreased.

Visibility is built in:

- Ceiling control panel is located to the upper right side

- Air-conditioning components are located on the upper rear corners of the cab

- Fuel tank is located out of line of sight below the left-hand side of the platform

- Optional loader view roof

- Liquid-crystal display (LCD) instrument cluster to easily monitor tractor functions

Optional loader roof with sunshade

Optional loader roof with sunshade

Instrumentation and controls

LCD dash

LCD dash

An LCD instrument cluster provides at-a-glance information on engine and power take-off (PTO) speeds for operators to have immediate vehicle information. The instrumentation and controls include:

- Tachometer

- Engine coolant temperature

- Hour meter

- Directional indicator light

- Fuel lever indicator

- Alternator indicator light

- Oil pressure indicator light

- Ground speed indicator

- Air filter restriction light

- Headlight dimmer switch

- Exhaust filter cleaning indicator

Electrohydraulic mechanical front-wheel drive (MFWD) engagement allows operators to easily and quickly engage MFWD when needed with minimal effort and is located on the right-hand console.

Electrohydraulic MFWD engagement

Electrohydraulic MFWD engagement

Designed for operator comfort

For additional operator comfort, the cab is fully insulated and includes:

- Left- and right-hand doors

- Sun visor

- Mechanical cloth seat (optional air)

- Air suspended seat

- Cup holder (two)

- Tilt/telescopic steering column

- Convenience power outlet

- Power outlet

- Front wiper with washer

- Air conditioning and heater

- Two monitor mounting bases

- Removable rear monitor plug

- Radio prep package with antenna cable

- Antenna

- Two speakers and wiring harness

- Internal rear-view mirror, adjustable height

- Two external fixed rear-view mirrors

- Basic fender upholstery

- Door-activated dome light

Instructional seat option

| Code | Description | 6100E | 6115E | 6130E | |

| 8254 | Instructional seat | Option | X | X | X |

Engine, 4.5L PowerTech™ engine

John Deere 6E Series Tractors feature the reliable and proven 4.5L (276 cu in.) two-valve PowerTech E engine.

The PowerTech E engine, used in 6100E, 6115E, and 6130E models, are diesel engines that can deliver up to 25 percent torque rise.

| Model | Engine | Emission level | Engine displacement | Rated engine speed |

| 6100E | PowerTech E | Tier 3 | 4.5L (276 cu in.) | 2100 rpm |

| 6115E | PowerTech E | Tier 3 | 4.5L (276 cu in.) | 2100 rpm |

| 6130E | PowerTech E | Tier 3 | 4.5L (276 cu in.) | 2100 rpm |

These engines are designed for performance, long life, and low maintenance costs. The two-valve engine design of the PowerTech E provides excellent torque, fuel efficiency, and durability. The PowerTech engine delivers:

- Clean performance

- Latest engine technology

- True customer value

The PowerTech E also features a rotary injection pump and mechanical governor.

12F/4R top shaft synchronized (TSS), 12F/12R PowrReverser™, 24F/8R TSS Hi-Lo, and 24F/12R (30k and 40k) PowrReverser Plus transmissions

Gear selection lever

Gear selection lever

Electrohydraulic left-hand reverser

Electrohydraulic left-hand reverser

For operators requiring more field speeds to achieve the most precise operating ranges, five transmission options are available in the 6E Series.

- 12F/4R TSS with wet clutch

- 24F/8R TSS Hi-Lo with wet clutch

- 12F/12R PowrReverser wet clutch

- 24F/12R (30 and 40k) PowrReverser Plus wet clutch

All 6E transmissions are equipped with a wet clutch to increase durability and operator comfort and reduce service time.

The 24F/8R TSS Hi-Lo and 24F/12R PowrReverser Plus transmissions offer 24 forward speeds for the ultimate in speed selection. Convenient push-button controls actuate the electrohydraulic high/low selector.

The forward lever selects one of three speeds, all synchronized shifts for on-the-go shifting with the use of the clutch. This same lever is where the high/low control buttons are located. The range lever selects ranges A, B, C, or D. Ranges C and D are fully synchronized. That means, when upshifting, operators can move from ranges B to C to D without stopping the tractor. On the downshift, operators can move from D back down to C without stopping.

Hi/Lo selector on gear lever

Hi/Lo selector on gear lever

The Hi/Lo feature benefits operators who frequently transport their tractors from field to field or find themselves in bog-down situations during rear power take-off (PTO) work. Operators can push the rabbit button (high) without having to depress the clutch to get a 20 percent increase in speed. They can also push the turtle button (low) to get a 20 percent decrease in speed, similar to downshifting or engine braking without having to grab another gear. The PowrReverser has a built-in engagement override valve for additional safety. This valve requires the clutch pedal to be depressed one time after each engine start before the transmission will begin to operate normally, giving the operator another opportunity to put all focus on the tractor.

Those selecting the 6E Series PowrReverser transmission are looking for unmatched performance. This transmission is ideal for working in tight areas where forward to reverse shifting is a primary occurrence, such as in barns, feedlots, and loader applications.

The 12F/4R TSS and 12F/12R PowrReverser transmissions offer five well-spaced ground speeds placing the operator in the important field-working range of 4 km/h to 12 km/h (2.5 mph to 7.5 mph). The 24F/8R Hi-Lo transmission will deliver 10 well-spaced ground speeds to match the correct speed for each application, and it can accelerate up to 31.6 km/h (19.6 mph), doing more in less time.

The optional PowrReverser Plus transmission 24F/12R will deliver 11 well-spaced ground speeds to match the correct speed for soil preparation or planting application with a top speed of 40 km/h (25 mph).

24F/12R PowrReverser Plus transmission includes:

- Wet clutch

- Platform-mounted shift levers (three gears, four ranges, with Hi/Lo selector)

- Left-hand reverser (F to R without clutching)

- Constant-mesh, helical gears

- Pressure-lubricated top shaft

- Neutral start switch

- Option of 40k

A dash-mounted PowrReverser modulation kit (LVB25727) is available to set the aggressiveness of the forward and reverse shuttle modulation that best fits the application or the operator's comfort level.

Operator controls

Hi/Lo and PowrReverser Plus high/low buttons

Hi/Lo and PowrReverser Plus high/low buttons

Two levers, one for speed and one for range, with the addition of an electrohydraulic left-hand reverser in PowrReverser transmissions, provide operators optimum control and maneuverability.

- Range lever (left-hand side in open operator station, right-hand side in cab) selects four ranges (A, B, C, D).

- Gear selection (right-handside) selects speeds 1, 2, or3 in the forward or reverse direction.

- Electrohydraulic left-hand reverser allows for quick and convenient shuttle shifting between forward and reverse at any speed (available for PowrReverser transmissions).

Forward and reverse speeds

All speed gears (1, 2, 3) are fully synchronized for shifting-on-the-go capabilities, putting less wear on the operator and saving them time in the field. In all 6E transmissions, gears are synchronized for low shifting effort while the operator is doing field or loader work and during transport.

The high and low speeds on the 24F/8R Hi-Lo and the 24F/12R PowrReverser Plus transmissions can be shifted without clutching while the tractor is under load. This makes for quick speed changes when operating in uneven conditions.

The ranges (A, B) are not synchronized. This means the tractor must be stopped for the operator to select the range. However, with operator input, the speeds have been well spaced out to minimize the need to change ranges within applications. The ranges (B to C, C to D, and D to C) are synchronized. That allows the operator to shift ranges on the go in transport and high-speed applications like operating a mower-conditioner.

Wet clutch

John Deere has led the industry in the innovation of wet clutches. In this wet-clutch design, five 17-cm (6.7-in.) diameter clutch disks provide optimum clutch modulation for smooth operation; the disks are oil-cooled for a lifetime of service.

The biggest advantage of a wet clutch is its ease of use, as the required force to depress the pedal is minimal. Also, with a wet clutch, the need for frequent adjustment and clutch mechanism changeover is eliminated.

Transmission options:

- 12F/4R TSS wet-clutch transmission

- 12F/12R PowrReverser wet-clutch transmission

- 24F/8R Hi-Lo wet-clutch transmission

- 24F/12R PowrReverser Plus (30k and 40k) wet-clutch transmission

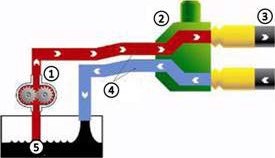

Open-center, gear-driven hydraulics

6E Series open-center hydraulics

6E Series open-center hydraulics

- Pump

- Selective control valve (SCV)

- Flow

- Operation circuit

- Sump

All 6E Series Tractors feature a gear-driven, open-center (constant-flow) hydraulic system with a maximum pressure of 19,500 kPa (2830 psi).

The tractor incorporates a triple hydraulic pump design. The implement, steering-transmission lubrication systems, and transmission all function separately; all three systems utilize a common reservoir resulting in ease of serviceability. Two selective control valves (SCVs) are in base with a third deluxe valve as optional equipment.

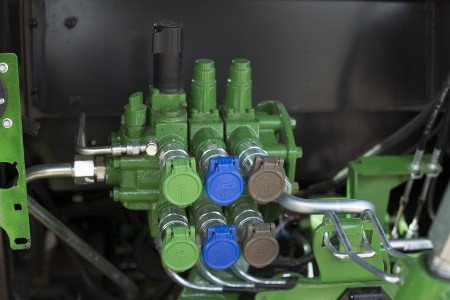

Hydraulics SCVs

To control a rear implement, two standard SCVs come as base for the 6Es and a third deluxe SCV is an orderable option.

Dual-standard SCV

Dual-standard SCV

Benefits:

- All SCVs feature four positions — neutral, raise, lower, and float

- Deluxe SCVs feature flow control

- Deluxe SCVs have three detents: pressure limit kick-out, spring center, and continuous detent

- Stackable design to easily add a third SCV if desired

Triple-deluxe SCV

Triple-deluxe SCV

BSJ10220 installation location

BSJ10220 installation location

SCV options

| Code | Description | Availability | 6100E | 6115E | 6130E |

| 3320 | Dual-standard SCV with ISO breakaway couplers | In base | X | X | X |

| 3330 | Three SCVs: two standard SCV plus one deluxe SCV with ISO breakaway couplers | Option | X | X | X |

| BSJ10220 | Third deluxe SCV attachment, conversion kit from two SCVs to three SCVs | Field install | X | X | X |

Pressure available when needed

Pressure for entire system is established by function requiring the highest pressure. As demand lessens, so does pump pressure and engine power requirement. Steering section (additional 28.5 L/min [7.5 gpm] in base equipment) provides full power when needed for steering. Transmission section (additional 28.5 L/min [7.5 gpm] in base equipment) provides hydraulic pressure for the power reverser transmission.

The steering and transmission circuit functions return to sump, giving improved system performance and cooling. By returning functions to sump, the system is simplified and provides faster service and increased uptime.

Remote flow rating

| Models | Rated flow | At engine rpm |

| 6100E, 6115E, 6130E | 72.3 L/min (19.1 gpm) | 2100 |

The steering side and transmission side of this pump provides an additional 28.5 L/min (7.5 gpm) respectively.

Dual 540-/1000-rpm rear power take-off (PTO)

PTO yellow knob

PTO yellow knob

540/1000 rpm PTO

540/1000 rpm PTO

The 6E Series Tractors feature an independent and electric 540/1000 rpm PTO as base equipment. For feeding, mixing, baling hay, or any other PTO application, the 6E Series 540/1000 rpm PTO can match up efficiently to any requirement.

An easy-to-use push/pull knob on the right-hand console allows the operator to quickly and smoothly engage and disengage the PTO. If the tractor is stopped or is being downshifted, the PTO rpm levels can be maintained. To engage the PTO, simply pull up on the knob. When the PTO is engaged, a light on the instrument panel illuminates. To disengage the PTO, simply push the knob back down.

Adding to operator safety, the tractor does not start with the PTO lever engaged. An alarm sounds if the operator attempts to leave the seat with the PTO engaged.

NOTE: Operators should disengage PTO before the engine is stopped.

The 6E offers a PTO wet clutch for a long, reliable lifetime of operation. The wet clutch eliminates the need for frequent adjustment and clutch mechanism changeover.

Reversible 540/1000 rpm PTO stub shaft

Reversible 540/1000 rpm PTO stub shaft

Reversible 540/1000 rpm PTO stub shaft

Operators can easily switch between 540 and 1000 rpm-driven implements simply by removing the stub shaft and reversing its position. The reversible 540/1000 PTO stub shaft is located in a dry cavity to allow changing from 540 to 1000 rpm or vice versa without any oil spillage. Just remove the snap ring to remove the shaft.

Serviceability

Tilt hood

The hood tilts to open wide, allowing unencumbered engine compartment access. An easy-reach tether cord allows access to effortlessly close the hood. Overriding the two gas struts permits the hooding up to 90 degrees. Unhooking the tether from the radiator support allows the operator to open the hood even further to provide better access for servicing the under-hood components.

The tilt-up hood provides easy access from the ground to:

- Coolant recovery tank

- Tiltable radiator assembly

- Air cleaner

- Front-mounted battery

Filter service intervals

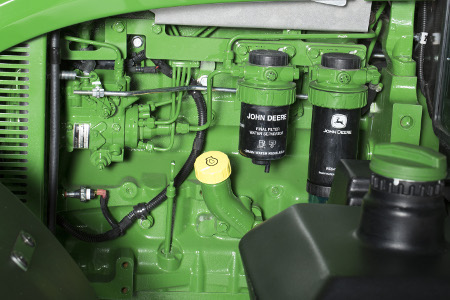

Fuel filters

Fuel filters

Vertical engine oil and fuel filters minimize spilling for cleaner and faster changes. 500-hour service intervals (when using John Deere Torq-Gard™ oil or Plus-50™ lubricant and filter) for engine oil and filter, fuel filter, and cab air filter reduce maintenance costs over the life of the tractor.

Two engine fuel filters provide the needed protection for the fuel system:

- One 30-micron primary filter

- One 2-micron final filter

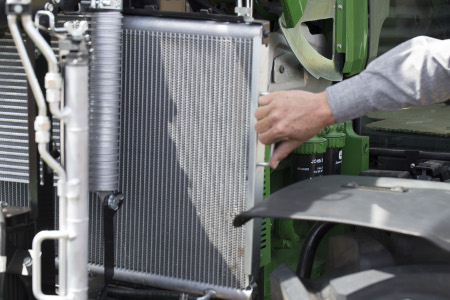

Radiator cleanout

Radiator cleanout

Radiator cleanout

Blowing out the radiator is easy and convenient with the 6E Series Tractors equipped with an in-base, sliding radiator assembly. Open the hood to clean out the radiator, fan, and cooling package. The condenser can be pulled out to one side for better access.

Coolant tank

The coolant recovery tank, located behind the air filter, is easily accessible from the ground.

Air filter

The engine air filter is located under the front of the hood above the radiator. Undoing the quick-attach fastener allows for fast and easy servicing - no tools required. The Power Core air filter removes more than 93 percent of foreign material before it reaches the filter element.

Cab air quality

Cab air filter

Cab air filter

The cab air quality system is comprised of two fresh air cab filters. A filter is located on the bottom side of the left- and right- side cab roof is easily accessible by removing two wing screws and a sealed cover plate.

Battery

12-V battery (cover off)

12-V battery (cover off)

12-V battery (cover on)

12-V battery (cover on)

Open the hood to access the battery. No tools are needed.

Transmission hydraulic oil sight gauge

Sight gauge

Sight gauge

Instead of using a dipstick, the transmission/hydraulic oil level is checked with a sight glass on the left side of the rear axle housing on 6E Series Tractors.

Transmission hydraulic oil filter

Hydraulic oil filter (behind 3-point hitch)

Hydraulic oil filter (behind 3-point hitch)

Transmission/hydraulic oil filter is conveniently located and designed to save the operator service time and reduce maintenance costs.

Change intervals:

- 500-hour transmission/hydraulic filter change

- 1000-hour transmission/hydraulic oil change

Windshield washer tank

![Windshield washer tank (right of selective control valves [SCVs])](https://salesmanual.deere.com/sales/salesmanual/images/AU/en/tractors/features_attachment/6e/windshield_washer.jpg) Windshield washer tank (right of selective control valves [SCVs])

Windshield washer tank (right of selective control valves [SCVs])

The windshield washer tank is conveniently located at the right rear of the cab for easy refilling. This would be the same washer fluid tank for the rear window wiper when ordered as a field-installed kit

Brake pedal adjustment

Brake pedal adjustment (left shown)

Brake pedal adjustment (left shown)

Easy brake pedal travel adjustment is provided on cab and open operator station (OOS) tractors. Turnbuckle linkage is located at the top side of left and right rear axles.