M732i

Trailed Sprayer

- 3,200 L tank volume

- 400 L rinse tank

- 280 L/min pump capacity

- ISOBUS ready

Features

Improved solution safety with closed transfer system

Easy connection to any closed transfer system

Easy connection to any closed transfer system

Fill and rinse the R700i Trailed Sprayer using a closed transfer system. You can plug directly into the container with an adapter that is widely used by crop protection manufacturers.

- Easy connection to any closed transfer system

- Increase safety by avoiding almost any contact with crop protection liquids

Save and protect crop with individual nozzle control

Individual nozzle control provides efficient localized crop protection application. The electronically controlled system reaches its ultimate potential when applied together with the PowrSpray™ system.

- Reduce costs by minimizing application skips or overlap

- Protect crops from overapplication of chemicals

Speedy precision with the dual-circuit PowrSpray™ system

Fill faster and spray more accurately with the unique dual-circuit PowrSpray system. It allows you to fill your sprayer in just 7 minutes (measured without priming) and gives you 98 percent* rate control accuracy.

- Save time with fast and efficient filling, spraying, and agitation

- Easy to operate with the convenience of push-button control

The dual-circuit layout maximizes efficiency and ease of use. Each circuit is completely independent, featuring a dedicated centrifugal pump and is optimized for specific functions. Cross contamination between the two circuits is not possible, helping to reduce rinsing requirements and residual liquid disposal.

Filling circuit

Filling circuit

Filling circuit

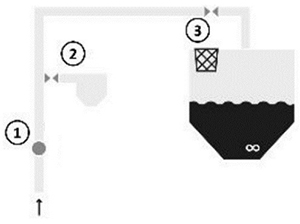

The filling circuit consists of the self-priming centrifugal filling pump (1) which fills the solution tank and provides clean water to the eductor. The filling circuit is not used during spraying and therefore not contaminated with chemicals and does not need to be rinsed.

Active Pause

Active Pause enables the operator to incorporate chemicals and rinse chemical containers with clean water without filling the solution tank.

Spraying circuit

Spraying circuit

Spraying circuit

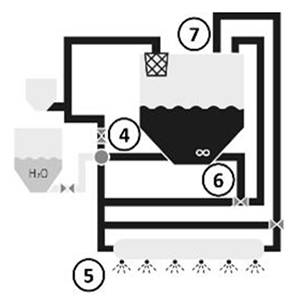

The spraying circuit is equipped with a centrifugal spray pump which provides liquid to the spray boom and agitation. Only the spray circuit gets in contact with the chemicals and therefore is the only part of the machine which needs to be rinsed

Direct Rate Control

Spraying pressure and application rate are controlled by adjusting the speed of the centrifugal spray pump via the load sense hydraulic pump drive. This load sense hydraulic drive enables a fast and accurate rate control.

*NOTE: The 98 percent accuracy figure is derived from JDLink™ data based on the John Deere piston diaphragm pump system compared to the John Deere 7.6-cm (3-in.) PowrSpray system and means that the set target rate is applied 98 percent of the time

Intuitive control of sprayer operations with the Solution Command system

Push-button filling, agitation, spraying, or rinsing

Push-button filling, agitation, spraying, or rinsing

Experience push-button filling, agitation, spraying, or rinsing on the R700i Trailed Sprayer. You have all the control you need either from the cab with the joystick or with the Solution Command system from the operator's station.

- Easy to control

- Speeds up the operation

- Accuracy and automation in filling, agitation, spraying, and rinsing

M732i