Automation 4.0 Activation

For Gen 4 CommandCenter™

- Use data from planting – or strip till and planting – to automatically create full-field guidance lines for secondary passes

- Let AutoTrac™ Turn Automation take over your turns, implement functions, and speed

- Crush harvest chaos through combine and grain cart controls with Machine Sync

- AutoTrac™ Implement Guidance places your tool exactly where it needs to be, even on sidehills and around curves

Features

Unlock all Gen 4 Precision Ag applications with CommandCenter™ Automation

AutoTrac™ Turn Automation available with the automation activation

AutoTrac™ Turn Automation available with the automation activation

Producers ready to take a step toward automation in their precision ag journey are ready for the CommandCenter Automation Activation. The bundle includes all of John Deere’s precision ag applications so that they can spend more time focusing on job quality and less time operating the machine itself.

The CommandCenter Automation activation gathers all available precision ag applications into a single orderable product for the 4600 CommandCenter Display with options to upgrade from other activation levels. This approach delivers more total customer value in a way that allows producers to use the applications they want throughout the crop production cycle without the worry and expense of licensing individual precision ag applications.

With CommandCenter Automation Activation 4.0, operators have access to the following applications:

- AutoTrac™ assisted steering system

- AutoTrac RowSense™ system

- Section Control

- In-Field Data Sharing

- AutoPath™ system

- AutoTrac Implement Guidance (passive implement guidance)

- AutoTrac Turn Automation

- Gen 4 Machine Sync

CommandCenter Automation Activation 4.0 is a non-transferrable display activation compatible with any John Deere machine equipped with a 4600 CommandCenter Display and v2 server. Functionality is dependent on machine configuration and may require additional hardware. Data created with a Gen 4 display is only compatible with John Deere Operations Center and can be transferred either wirelessly or via a USB drive with 4- to 32-GB capacity

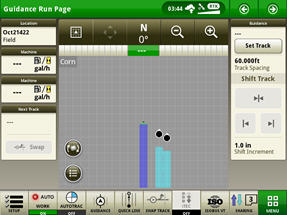

Automatically create AutoTrac™ guidance lines based on first field pass with AutoPath™ system

Create guidance lines with AutoPath that can be used on subsequent passes

Create guidance lines with AutoPath that can be used on subsequent passes

For large row-crop producers, setting up guidance lines in standing crops is a challenge. The process is slow, and there is no guarantee that the machine will run accurately between crop rows.

The AutoPath system automates data from the first documented pass to address these challenges. During the first pass, a map of all rows is created. AutoPath uses this data to automatically create accurate, full-field guidance lines for secondary passes such as planting, side dress, spraying, and harvest. Setup time and crop damage is reduced, and operators know which rows to start on, regardless of equipment width.

Make a perfect, repeatable turn at the end of every pass

You are human. Accurate and consistent turns are difficult to manually repeat throughout a long workday, especially when the dust kicks up and the sun goes down.

You are also a farmer. We understand that you are always striving to do your job better.

Easily complete end-of-pass turns no matter your in-cab experience

Easily complete end-of-pass turns no matter your in-cab experience

Whether you are planting, seeding, or harvesting, as the operator, you must be on top of your game all day, every day; performing various tasks at the right time and in the right place to maximize your inputs. As the hours pass and fatigue sets in, machine maneuvers and performance can become inconsistent and lead to rework or mistakes you must live with the rest of the season.

AutoTrac™ Turn Automation (ATTA) addresses these challenges head-on, by planning and automating precise, repeatable, and efficient turns at the end of each pass. Set up the display to fit your operation, and let ATTA go to work for you.

ATTA offers numerous benefits to the operator:

- The power to focus on the job at hand, making necessary adjustments and better agronomic decisions on the go

- The ability to watch the tractor/implement or combine/header more closely, allowing for proactive adjustments instead of reactive fixes

- The capacity to more diligently watch for damaging obstacles such as rocks, washouts, or holes throughout the field

- The potential to increase productivity through faster, more efficient, and smoother turns in the field’s headland, no matter who is in the operator’s seat

- BONUS: ATTA for tractors incorporates end-of-row functionality, like speed and implement control, that takes this already beneficial feature to the next level

- Operators can enjoy more hands-free time through automating a high repetition task, resulting in reduced stress levels

Precisely place the row where it is supposed to be with AutoTrac™ Implement Guidance

Plant accurate rows

Plant accurate rows

The goal of all producers is to have inputs, such as seed or fertilizer, placed into the ground in the most accurate way possible. With the increasing cost of inputs and adoption of farming practices that need precision, such as strip-till applications, accuracy at the implement has become increasingly important.

AutoTrac Implement Guidance helps maximize the use of inputs by increasing accuracy and repeatability at the implement thanks to a second receiver on the implement. Having a second StarFire™ receiver located on the implement allows the tractor to guide the implement through the field with additional accuracy, even on curved passes and sloping terrain. AutoTrac Implement Guidance (passive) commands the tractor to the correct location to keep the implement on the guidance line. In applications utilizing AutoTrac Implement Guidance, seeds are more consistently placed to take full advantage of pre-applied nutrients. This level of precision allows implement guidance to reduce overall input costs.

Reduce skips and overlaps with Section Control

John Deere Section Control switches boom sections on or off, reducing overlap and improving product placement.

Key features of John Deere Section Control include:

- Automatic control of sprayer sections when passing across:

- Previous coverage

- Exterior and interior boundaries

- Established headlands (buffer zones)

- Improve efficiency by reducing overlap, skips, input costs, and operator stress

- Easier setup with distance-based tuning

John Deere Section Control is available as part of the CommandCenter™ Premium application and requires a StarFire™ position receiver.

Reduce operator stress while following crop rows with AutoTrac™ RowSense™ system

AutoTrac RowSense system

A relaxed operator using AutoTrac RowSense software in an R4038

A relaxed operator using AutoTrac RowSense software in an R4038

Combine with RowSense sensor

Combine with RowSense sensor

Hagie™ STS14 with RowSense sensor

Hagie™ STS14 with RowSense sensor

Post-emergence operations such as spraying fungicide in July or harvesting corn in October can be stressful for operators. On top of steering the machine, an operator is required to monitor several other areas such as spray rates, ground terrain, grain or forage quality, or managing tender trucks and grain carts. Operating at night, in windy conditions, or while harvesting lodged corn can add even more stress for the operator.

Using feelers that engage the corp rows, AutoTrac RowSense has revolutionized the ability to use AutoTrac for post-emergence applications in later-season corn.

A study using advanced, eye-tracking glasses determined where an operator’s attention is focused while operating a sprayer through tall, standing corn. Without AutoTrac RowSense or Vision, the operator spent about 82.5 percent of the time looking forward. When AutoTrac RowSense or Vision was utilized, the same operators only spent 70 percent of the time looking forward and more time watching sprayer booms and monitoring machine performance on the vehicle display. AutoTrac RowSense focuses on steering so the operator can focus on other value-added tasks.

Hagie is a trademark of Hagie Manufacturing Company, LLC and similar to John Deere branded equipment, John Deere will also support Hagie equipment.

Use equipment and people even better with In-Field Data Sharing

Using Gen 4 In-Field Data Sharing, up to six tractors, sprayers, nutrient applicators, or combines can share as applied maps and guidance lines to reduce overlap, improve product placement, and monitor job quality in other machines. Equipment can work together at the same time or use maps created earlier by another machine to increase efficiency.

Three machines sharing coverage

Three machines sharing coverage

Sharing as-applied maps

Sharing as-applied maps

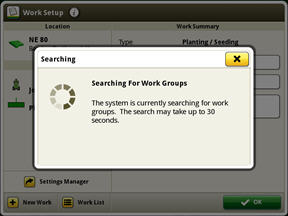

Using a streamlined setup process, In-Field Data Sharing matches maps and guidance lines together based on the information selected in the Work Setup screen, the same information is needed to document an operation. Setup items can be sent to the display from Operations Center for selection to make setup even easier.

Searching for other work groups

Searching for other work groups

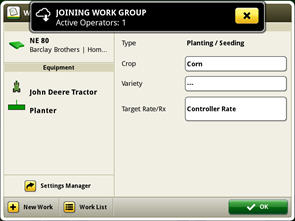

Joining a work group

Joining a work group

The information needed depends on the operation:

- Planting and seeding: Client, Farm, Field, and Crop

- Product application: Client, Farm, Field, and Product or Tank Mix

- Harvest: Client, Farm, Field, and Crop

Automate grain cart control while unloading on-the-go with Gen 4 Machine Sync

Filling the grain cart in the field

Filling the grain cart in the field

Harvest is hectic. Producers are focusing on getting all the crop from the field to the bin within a tight harvest window. Using Machine Sync, those producers can focus more on grain harvest and grain quality, and worry less about keeping the grain cart under the spout when unloading on the go. Gen 4 Machine Sync provides a solution to harvest stress by creating a wireless network between the tractor and combine to enable on-the-go unloading by synchronizing tractor speed and direction of travel with the combine.

Machine Sync works with In-Field Data Sharing to show the location of all combines and tractors within the fleet of Gen 4 machines harvesting in the field. Knowing the exact location of multiple combines as well as their grain tank fill level and unloading auger status allows the grain cart operators to be in the right place at the right time.

Activate Gen 4 display software remotely

Over-the-air activations were enabled with the 18-1 software update to the Gen 4 displays. With that software update or newer, a John Deere dealer can send activations to a Gen 4 display without leaving the office. Over-the-air activations also eliminate the need to manually enter long activation codes like was done previously. This also eliminates multiple trips between the cab and the farm office to enter codes and verify completion.

NOTE: Over-the-air activations requires a current JDLink™ Connect subscription and Mobile Telematics Gateway (MTG). Planter and platform activations and subscriptions cannot be updated over-the-air.