1725NT

Planter

- 8-row, 762 mm (30 in.) spacing

- Transport width under 3.05 m (10 ft.)

- 1.6 bushel hoppers

Features

1725NT frame

Stack-fold planter frame

Stack-fold planter frame

1725NT Planter frame

1725NT Planter frame

The 1725NT utilizes an integral, stack-fold frame that allows for a transport width of approximately 3.05 m (10 ft) and a height of just over 4 m (13 ft). Operators who drive on narrow roadways or work in small fields will find the narrow transport frame, without lift-assist wheels, to be especially useful in situations where maneuverability is limited.

This design also allows for the vacuum to be integrated into the frame without adding clutter to the bar. This means a cleaner look with better visibility from the operator station.

The 1725NT also includes 40.6-cm (16-in.) notched disk markers in the base machine, with an option for less markers. These markers act independent of the frame position and are controlled by a selective control valve (SCV). The notched disk design allows for a more aggressive marking capability, especially in minimum-till or no-till conditions.

MaxEmerge™ 5e overview

The MaxEmerge 5e is designed to improve population accuracy, spacing, and avoid wasting inputs for maximizing yield. The "e" in MaxEmerge 5e stands for electric drive. It is driven by one electric motor per meter with a small controller. This does away with the shafts and drivelines of a typical mechanical drive. That means more reliability, less maintenance, and easier access to row-unit components. For producers who want uniform seed spacing, the MaxEmerge 5e is a great option.

One of the biggest advantages of the MaxEmerge 5e is how it improves population accuracy by compensating for curves on the outer rows of the planter. The MaxEmerge 5e row-unit eliminates shafts and drivelines from the planter, allowing better access to row-unit components and decreased planter maintenance. Additionally, the MaxEmerge 5e allows corn and soybean growers to achieve up to a 20 percent improvement in population accuracy on the outer rows of a 24-row planter while planting on curves utilizing curve compensation.

While the MaxEmerge 5e uses a seed tube, it offers some of the same important advantages as ExactEmerge row units. The MaxEmerge 5e also improves reaction to population changes in the field when conditions dictate a higher or lower population, enabling producers to more accurately plant to the variable-rate prescription that maximizes profit potential. High-performance vacuum automation automatically maintains the target vacuum setting throughout the day with less time monitoring and making adjustments. It uses the SeedStar™ 4HP system and is compatible with Connect Mobile monitoring for near real-time, row-by-row planting performance. Depending on planter model, the MaxEmerge 5e package unlocks additional options like easy adjust row cleaners, individual row hydraulic downforce, and pneumatic closing wheels.

The MaxEmerge 5e delivery system options include mini-hoppers with Central Commodity System (CCS™), 56.4-L (1.6-bu) hoppers, and 105.7-L (3-bu) hoppers.

NOTE: MaxEmerge 5e row-units are compatible with the following models: 1725NT, 1725C, 1725 CCS (not available on twin row), 1775NT, 1795, DB44, DB60, DB66, DB80, DB88, and DB90 (not available on 54R 50.8 cm [20 in.]).

Commodity storage

56.4-L (1.6 bu) hoppers available in base equipment

56.4-L (1.6-bu) hopper

56.4-L (1.6-bu) hopper

Access to the meter under the hopper

Access to the meter under the hopper

The 1725NT utilizes a unique 56.4-L (1.6 bu) hopper that can be tilted and braced upwards to gain easy access to the meter for adjustments or cleanout.

This design also has a shutoff door to allow for meter access when seed is still in the hopper.

Vacuum automation

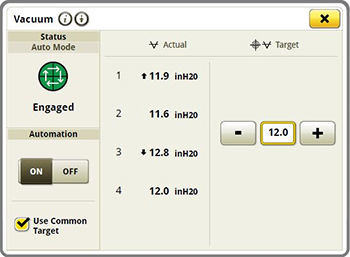

Vacuum automation screen

Vacuum automation screen

Vacuum control has been defined. Before vacuum automation, an operator set the vacuum level by adjusting the hydraulic flow through each selective control valve (SCV). Many variables altered the vacuum level while the hydraulic flow stayed constant. This could have resulted in under or over populating, which may have impacted singulation. With vacuum automation, all that needs to be done is set the desired vacuum level and let the monitor do the work of adjusting the hydraulic flow. Should vacuum changes occur, the software in the monitor will fluctuate the SCV flow to achieve the desired vacuum level.

Vacuum automation requires SeedStar™ 4HP monitoring. The system controls SCV flow based on the vacuum pressure sensor. The tractor must be a John Deere with Tractor Electronic Control Unit (TECU) 3 controller area network (CAN) system for this feature to be compatible. The vacuum automation feature will control all vacuum fans if they are on their own SCVs. More vacuum fans make the planter more valuable and easier to operate.

Vacuum automation is not compatible with Interim Tier 4 (IT4) 6R Series Tractors.

Vacuum automation works with MaxEmerge™ 5e and ExactEmerge™ planting technologies. It’s available on Deere models as well as select DB models.

Unit-mounted row cleaner with convenient screw adjustment

Screw-adjust unit-mounted row cleaner

Screw-adjust unit-mounted row cleaner

Row cleaners are a valuable tool in reduced tillage planting conditions. The row cleaner helps to clear residue from the path of the opener, ensuring good row-unit operation. The row cleaner utilizes two angled wheels which engage the soil surface and residue, sweeping them aside.

Row cleaners provide many agronomic benefits, including quicker soil warmup and germination, and reduced hair pinning of residue into the seed furrow. Row cleaners can also provide a smoother ride for the gauge wheels, resulting in less row-unit bounce and a more uniform seeding depth.

The screw-adjust unit-mounted row cleaner is mounted directly to the face plate of the row-unit, placing the ground-engaging components just in front of the row-unit opener blades and depth gauge wheels. This close proximity allows the gauge wheels to control the depth of the row cleaner as well as the row-unit.

This compact design also allows greater compatibility with fertilizer openers and other planter attachments.

SharkTooth® wheels

SharkTooth wheel

SharkTooth wheel

The unit-mounted row cleaner features the SharkTooth wheel. The beveled, sharpened edge of the teeth on the SharkTooth aggressively cut tough residue that lies in the path of the row-unit. The curved tooth design sweeps a clear path for the openers and resists residue buildup.

The wheels are arranged in a staggered fashion with one wheel leading the other, ensuring complete clearing of the row-unit path. The wheels can also be run side-by-side if desired, by simply relocating the wheels to existing holes on the row cleaner bracket.

The bearing on the SharkTooth wheel is sealed and requires no regular maintenance. Bearing shields are used between the wheel and the mount bracket to prevent residue wrapping and buildup around the bearing housing.

Adjustability

Row cleaner adjustment knob

Row cleaner adjustment knob

The unit-mounted row cleaner offers a convenient screw adjustment feature for changing the depth setting. The acme screw is enclosed within the structure of the mounting bracket, providing protection from the elements.

The adjustment knob for the screw adjustment is accessible from the top of the parallel arms. The knob can be adjusted by hand, or by using a socket.

The adjustment is detented in 1.6-mm (1/16-in.) increments, allowing for quick, easily repeatable adjustments across all rows of the planter.

An indicator rod and scale on the front of the row cleaner bracket indicate the current setting. If a condition is encountered where use of the row cleaner is not desired, it can be set so that the wheels do not engage the soil surface.

Operational notes and compatibility

Use of row cleaners is not recommended when surface application pre-plant herbicide is used prior to planting. When using pre-plant incorporated herbicide, the row cleaner should be adjusted to minimize soil disturbance so as not to reduce the effectiveness of the incorporated herbicide.

Drive chain shields are recommended for use with row cleaner attachments.

Two different models of screw-adjust, unit-mounted row cleaners are available; the standard row cleaner for 762-mm (30-in.) row spacing and the narrow row cleaner for 508-mm (20-in.) or 558.8-mm (22-in.) row spacing.

NOTES:

-

Screw adjust, unit-mounted row cleaners are fully factory installed when ordered with the planter

-

Not compatible with use of frame-mounted coulter

-

Row spacing less than 762 mm (30 in.) requires the narrow row cleaner option.

-

For 1795 12/23, 12/24, 16/31, and 16/32 row machines, unit-mounted row cleaners are provided on the front rank of rows only.

-

For DB60 47R15 machines, unit-mounted row cleaners are provided on the row-units with short parallel arms only. They provide the 24 rows set on 762-mm (30-in.) spacing row cleaners.

-

Not compatible with the use combination of long parallel arms and MaxEmerge 5e row-units.

SharkTooth is a trademark of Yetter Manufacturing, Inc.

SeedStar™ 3 HP monitoring system

SeedStar 3 HP overview

SeedStar 3 HP shown on the GreenStar™ 3 2630 Display

SeedStar 3 HP shown on the GreenStar™ 3 2630 Display

Building upon the foundation of previous SeedStar monitoring, the SeedStar 3 HP monitoring system takes planter monitoring to the next level. When paired with the GreenStar 3 2630 Display, the SeedStar 3 HP monitoring system provides critical information about the planting process to the operator within the tractor cab. SeedStar 3 HP is compatible with the GreenStar 3 2630, the Gen 4 4200 CommandCenter™ Display, the Gen 4 4600 CommandCenter Display, the 4240 Universal Display, and the 4640 Universal Display. SeedStar 3 HP is not compatible with the Gen 4 Extended Monitor.

Detailed planter performance information allows the operator to make adjustments needed for planter optimization. After all, with rising costs, it is imperative to make sure that every seed is planted accurately and precisely within the seed furrow for maximum yield potential.

The SeedStar 3 HP planting functions are fully integrated with the full spectrum of Precision Ag Technology applications such as John Deere Section Control for Planters, GreenStar, AutoTrac™ assisted steering system, John Deere Operations Center, JDLink™ telematics system, and others. Integrated planting technologies, for better asset utilization and ease of use, is just part of what SeedStar 3 HP provides.

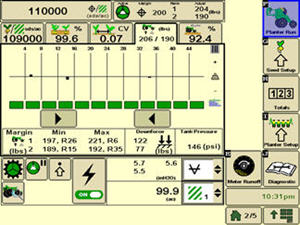

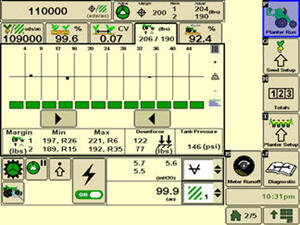

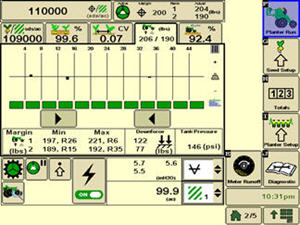

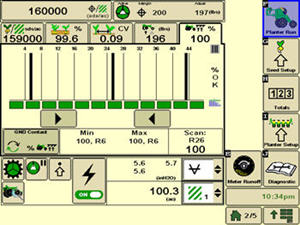

SeedStar 3 HP main run page

SeedStar 3 HP main run page

SeedStar 3 HP main run page

SeedStar 3 HP has an updated main run page layout. With the use of tabs toward the top of the screen it is much easier to navigate through readings such as population, singulation, spacing, downforce, and ride quality. If for some reason an issue arises with a row-unit, the tab will turn red indicating there is an issue. The tab can be pushed and lead to what is causing the issue. Inside each tab, there will be a bar graph detailing information specific to that tab. The picture shows what a population bar graph looks like. This layout improves functionality and overall ease of use while planting.

SeedStar 3 HP seed singulation monitoring

SeedStar 3 HP seed singulation planter run page

SeedStar 3 HP seed singulation planter run page

Understanding meter singulation performance on the planter is critical to minimizing the amount of seed multiples and skips. As a result, the SeedStar 3 HP monitoring system provides real-time information, from the redesigned seed sensors placed in each belt cartridge, about the overall seed singulation performance.

As seen in the screen shot image to the left, overall singulation performance is seen in the tab at the top of the screen. Seed skip and multiple sources of information are displayed below the bar graph of the run page. This provides the operator a better understanding of relative seed multiple and skip data on a row-unit basis within one easy glance at this run page.

Also, within the seed singulation planter run page, information about row-units with the highest percentage of seed multiples and skips is provided in order to make necessary adjustments for better planter optimization.

SeedStar 3 HP row-unit downforce planter run page

SeedStar 3 HP downforce planter run page

SeedStar 3 HP downforce planter run page

With changing field conditions, it is important to monitor down force to ensure consistent seed placement. Seeds placed too shallow or too deep can impact emergence and affect yield.

With the SeedStar 3 HP monitoring system, row-unit downforce information is measured by the downforce sensor and sensor nodes and transmitted to the GreenStar Display in the tractor cab. The row-unit downforce information is displayed on the top portion of this run page with more row-unit downforce information on the lower portion.

Active pneumatic downforce takes SeedStar 3 HP even further by removing constant downforce adjustments from the operator and actively controlling the downforce system to maintain a desired target margin. Just set the row-unit target margin value and the active pneumatic downforce system works automatically to make sure the planter maintains this value-achieving, precise soil penetration and consistent planting depth without sidewall soil compaction. This frees the operator from constantly making manual downforce adjustments as conditions change.

SeedStar 3 HP ride quality and ground contact run page

SeedStar 3 HP ride quality and ground contact run page

SeedStar 3 HP ride quality and ground contact run page

The fifth tab from the left in SeedStar 3 HP is a shared tab between ground contact and ride quality. Operators may change between the two criteria based on their planter setups or personal preferences. Ground contact displays the percentage of time the row-units are engaging the ground, the load is measured via a sensor through the gauge wheels. Ground contact is recommended when using ExactEmerge™ row-units to ensure the row-unit is maintaining proper depth at higher planting speeds.

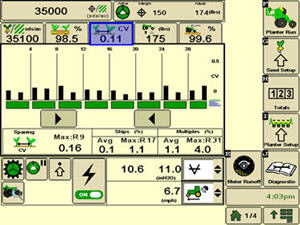

SeedStar 3 HP seed spacing monitoring

SeedStar 3 HP seed spacing planter run page

SeedStar 3 HP seed spacing planter run page

Throughout the planting process, obtaining good seed spacing is critical towards achieving plant growing conditions for maximum yield potential.

Today, many items are adjusted on the planter prior to planting to optimize overall seed spacing performance. But after such adjustments are made, information about the actual seed spacing performance during planting was missing within the planter monitoring system. With SeedStar 3 HP, seed spacing information is transmitted live via the GreenStar Display to show the operator exactly what is happening with the planter behind them.

The SeedStar 3 HP transmits seed spacing information onto the bar graph (shown to the left) for easy understanding of planter seed spacing performance. Also, information about seed skips and multiples are provided to help understand actual planter meter performance and other related system functions in order to make necessary adjustments if needed.

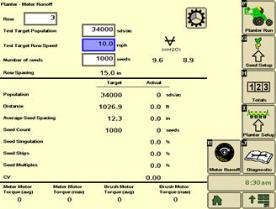

SeedStar 3 HP meter runoff page

SeedStar 3 HP runoff page

SeedStar 3 HP runoff page

On SeedStar 3 HP, the meter runoff page allows growers to test meters before going to the field. Growers can test the meters without removing them and have confidence in their planter’s performance before going to the field. Many parameters can be viewed during this test such as: singulation, seed count, skips, multiples, coefficient of variation (cv), etc. This test assures that the meter is in healthy condition and ready to plant when conditions are appropriate.

Other SeedStar 3 HP monitoring features include:

- Capable of monitoring individual row-unit and overall planter performance in terms of seed spacing, singulation, and row-unit downforce

- On-screen indication of sensor node/down force sensor assemblies once configured within the monitor settings application

- Full-color display icons for easy recognition and overall aesthetics

- Pneumatic downforce system controls with the GreenStar Display application

- A run page that allows operator to view relative population levels of all rows on one screen

- Mapping of actual and target seed rates can be mapped in APEX™ software

- Reprogrammable utilizing controller area network (CAN) via Service ADVISOR™ diagnostics system or Service ADVISOR Remote with JDLink™ subscription

- User-configurable high fertilizer pressure alarm that allows the operator to be warned when fertilizer pressure reaches a specific level

- Automatic Fast Start for SeedStar 3 HP. This ensures that seeds will be place accurately when starting from a stop.

- Automatic tractor speed source selection. When equipped with an 8000/9000 Series Tractor, the system selects the radar speed or allows for manual speed input selection.

Components and operation

Planter main controller

Planter main controller

Row-unit controller (RUC) with two electric motors

Row-unit controller (RUC) with two electric motors

The SeedStar 3 HP monitoring system contains the following components in order to support the planting data transfer to the GreenStar Displays:

- Planter main controller

- Sensor node(s)

- Downforce sensor assembly

- Electric power gen controller

- Electric power gen (EPG)

- Row-unit controller (RUC)

The row-unit controller processes the row-unit data from the sensor node assemblies located on the row-unit head casting. The processed information is then sent to the planter main controller to be integrated into the displayed information being sent to the GreenStar Display.

Downforce sensor assemblies are found on row-units with sensor nodes installed. The downforce sensor assembly is put together with the gauge wheel depth-adjustment handle and provides gauge wheel pressure information to the respective sensor node for data processing.

SeedStar downforce sensor installed

SeedStar downforce sensor installed

SeedStar downforce sensor assembly unit

SeedStar downforce sensor assembly unit

Depending on the planter size, different configurations of sensor nodes and downforce sensors are installed in support of the SeedStar 3 HP monitoring system.

SeedStar 3 HP is only available with the MaxEmerge 5e and ExactEmerge row-unit compatible planters built prior to model year 2018. Retrofit kits, DR models, and custom-built planters will continue to use SeedStar 3 HP in model year 2018.

Increase productivity with ExactEmerge™ trench delivery system and BrushBelt™ delivery system

It is very challenging to get the crop planted during the optimum planting window or as close to the optimum planting day as possible. Rate-of-yield loss accelerates greatly after the optimum window has passed. This is especially true in the northern U.S. and Canada. ExactEmerge maintains accurate speed placement at higher speeds; growers can avoid missing that peak planting time, thereby helping to get the highest crop yields.

Yield loss after optimum planting day

Yield loss after optimum planting day

With the BrushBelt trench delivery system, the spacing in the trench does not change from even to uneven terrain. This can be a problem with a traditional seed tubes. Seed bounce and ricochet may occur as slopes increases, ultimately decreasing seed spacing performance.

The design of the BrushBelt system provides the best solution for the lowest release of seed to the bottom of the trench. The use of a brush provides the meter with an infinite amount of placement opportunities for each seed. This is what gives producers the confidence that every seed will have the desired spacing that a seed tube cannot provide.

Maintenance-free BrushBelt system

Maintenance-free BrushBelt system

When the brush comes around the pulley, it expands and allows the seed to be transferred from the bowl to the brush very easily. The brush then carries the seed down toward the trench, ensuring that there is no movement as it moves down the length of the cartridge.

Once the brush reaches the lower pulley, the BrushBelt system expands again to loosen the grip on the seed, and the centrifugal force releases the seed. Another advantage with the BrushBelt system and cartridge at all speeds up to 16.1 km/h (10 mph) is the ability to match the seed rearward trajectory to the forward ground speed of the planter. This provides a dead drop of the seed with no bounce and no roll at the bottom of the trench.

BrushBelt conditioner engages brush bristles

BrushBelt conditioner engages brush bristles

John Deere’s ExactEmerge cartridge is self-cleaning. When an operator uses seed treatments or is forced to plant in less than ideal soil conditions, the design of the trench delivery system sheds buildup from the BrushBelt. A brush conditioner is located at the bottom of the cartridge to remove remaining residue and prevent the bristles from sticking together.

Brush proximity helps clean sensor

Brush proximity helps clean sensor

Another advantage over a seed tube is that the BrushBelt system also acts as a cleaner to the seed sensor compared to a seed tube.

BrushBelt removed from trench delivery system

BrushBelt removed from trench delivery system

The BrushBelt system requires no maintenance and has a wear life designed to match the wear life of the other wear components. Since operations vary, as do soils and field content, it is recommended to replace the BrushBelt after noticeable wear or decreased performance.

Changing the belt is easy. One latch removes the meter over the trench delivery system. Grab the cartridge by the grip and pull toward the body, releasing it from the electric motor fitting. Lift the trench delivery system up and remove the sensor wiring harness to completely pull the cartridge out of the row-unit.

There are two plastic covers that snap off to uncover the belt; remove the covers and then twist the circular spring-tensioner dial with the yellow arrow on it to release the tension on the springs. Once tension has been removed, pull the belt out. It is also recommended to change the stainless-steel wear strip at this time as well, which also slides right out of place without the use of tools.

NOTE: It is recommended to use a talc/graphite mixture with ExactEmerge. Best results have been 80 percent talc and 20 percent graphite. For certain regions and territories, talc and talc/graphite mixes are restricted from use; in this case, use a wax-based fluency agent.

Dual 56-V electric motors for ExactEmerge™ row-units

Two 56-V brushless electric motors

Two 56-V brushless electric motors

Improve productivity with two 56-V brushless electric motors

Improve productivity with two 56-V brushless electric motors

Two 56-V brushless electric motors provide ExactEmerge the upper hand over any other row-unit on the market. One motor controls the high-performance meter and the other powers the BrushBelt™ delivery system. Both feature a closed loop system ensuring they operate at the correct rpm.

The motor is controlled at a rate of 200 times per second and a decision is made every 5 milliseconds. The controller also keeps each motor operating at independent speeds of each other. The meter speed is determined by a combination of ground speed and desired population rate while the BrushBelt speed stays consistent with the forward ground speed of the planter in order to place the seed at the bottom of trench.

Brushless motors are maintenance free

Brushless motors are maintenance free

Industry-proven 56-V brushless motors give confidence to the operator that the row-unit will perform in any condition. The advantage of 56-V over 24-V electric motors is a lower amperage draw.

Brushless motors are maintenance free and give the producer the most optimal solution to achieve the highest performance and the lowest amount of work to the planter.

Built-in RowCommand™ system

Built-in RowCommand™ system

Manage seed output, reduce yield drag, and improve harvest capabilities are features built in to every ExactEmerge row-unit with electric motor shutoffs.

The electric drive version of RowCommand row-unit has the potential to get 2 to 8 percent reduction in seed usage from being able to control the meter and BrushBelt rather than a clutch disengaging and some seeds still falling down the seed tube.

Curve compensation

Utilize curve compensation when planting

Utilize curve compensation when planting

Terraces or waterways are two of many field obstacles that make planting on a curve challenging. When planters utilize drive shafts, they are not able to control each individual row-unit; as a result, planting on a curve presents an issue of maintaining 100 percent population. Since the inside rows are moving slower than the outside rows, the inside rows will be over populating while the outside rows are under populating.

With ExactEmerge™ planters and equipped MaxEmerge™ 5e planters, the curve compensation feature allows each row to receive an individual signal based on the speed at which the row-unit is moving, maintaining the correct population across the width of the planter. Without curve compensation, there could be as much as a 24 percent drop in population accuracy, which is equivalent to 8,600 seeds per acre when planting at 36,000 seeds per acre. Curve compensation measures acceleration within the main planter controller and utilizes speed inputs to ensure each row has the desired population accuracy.

Mobile row-unit runoff

The first day of planting season can be as productive as the last with mobile row-unit runoff. The mobile row-unit runoff activation on the planter main controller (PMC) allows operators to make adjustments to maximize row-unit performance from a mobile device at the rear of the planter for both preseason and in-season use - all enabled through the PlanterPlus™ app.

Mobile row-unit runoff allows growers to perform test-stand functions from a mobile device connected to the planter.

The row runoff test provides complete diagnostic checks both preseason and in season. With the row-unit runoff test, the operator can make adjustments from the mobile device, including vacuum pressure, to determine the optimum meter and vacuum settings. This app functionality will help avoid making trips to the cab while validating meter performance.

During preseason planter inspections and set up, utilize the meter performance test to validate meter accuracy, similar to a test stand without leaving the farm. Test all systems on the planter, not just the meter, providing confidence that all planter systems are ready to plant. Reports are generated from the test providing information the operator can save and send for future reference.

Before heading to the field, the operator will benefit from knowing the best row-unit and vacuum settings for each variety selected to plant that spring.

Watch this video to see mobile row-unit runoff in action.

Mobile row-unit runoff will work with any model year 2017 or newer ExactEmerge™ or MaxEmerge™ 5e equipped planter. Mobile row-unit runoff can be added to model year 2017 electric drive machines with attachment AA93169.

For model year 2018 and newer ExactEmerge planters, mobile row-unit runoff is included in base equipment. For model year 2018 and newer MaxEmerge 5e planters not equipped from the factory, mobile row-unit runoff and Easy Fold can be added with attachment AA97849 (only available with 1775NT and 1795 Planters with a 2-point hitch and DB Planters).

NOTE: Mobile runoff utilizes PlanterPlus app available on select iPad® tablets, iPhone® smartphones, and Android™ devices.

Mobile row-unit runoff and Easy Fold aftermarket for field conversion kits

The below software bundles include the functionality explained above for machines not ordered with the feature from the factory. Compatible machines include all the necessary sensors and harnesses needed to make the feature function. The attachment part is software only. Follow the guide below for ordering and installation.

Mobile runoff ordering and software push guide

iPad and iPhone are trademarks of Apple Inc. Android is a trademark of Google LLC.

1725NT

Related Products

-

1705 Planter

1705 Planter -

1705 Twin Row Planter

1705 Twin Row Planter -

1725 CCS Stack Fold

1725 CCS Stack Fold -

1725 Integral Stack-Fold Planter

1725 Integral Stack-Fold Planter -

1725C Planter

1725C Planter -

1735 Planter

1735 Planter -

1745 Compact Planter

1745 Compact Planter -

1755 Drawn Planter

1755 Drawn Planter -

1765 Flex Drawn Planter

1765 Flex Drawn Planter -

1765 Rigid Drawn Planter

1765 Rigid Drawn Planter -

1775 Flex Drawn Planter

1775 Flex Drawn Planter -

1775NT 12Row30 Drawn Planter

1775NT 12Row30 Drawn Planter -

1775NT 16Row30 Drawn Planter

1775NT 16Row30 Drawn Planter -

1775NT 24Row30 Drawn Planter

1775NT 24Row30 Drawn Planter -

DB44 24Row22 Planter

DB44 24Row22 Planter -

DB66 36Row22 Planter

DB66 36Row22 Planter -

DB80 32Row30 Planter

DB80 32Row30 Planter -

DB80 48Row20 Planter

DB80 48Row20 Planter -

DB88 48Row22 Planter

DB88 48Row22 Planter -

DB90 36Row30 Planter

DB90 36Row30 Planter -

DB90 54Row20 Planter

DB90 54Row20 Planter -

DB120 48Row30 Planter

DB120 48Row30 Planter -

DR12

DR12 -

DR16

DR16 -

DR18

DR18 -

DR24

DR24 -

ExactEmerge™ Row Unit

ExactEmerge™ Row Unit -

MaxEmerge™ 5 Row Unit

MaxEmerge™ 5 Row Unit -

MaxEmerge™ 5e Row Unit

MaxEmerge™ 5e Row Unit