673

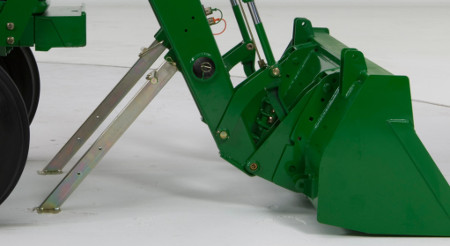

Loader

- Mechanical self-leveling

- Compatible with the 6100E, 6115E and 6130E

- Parking Stands

Features

Parking system

Parking stands

Parking stands

Features

The mast-to-mounting frame connection point is easily viewed from the operator's seat, making it easier to insert the mast into the mounting frame when parking.

The mast is shorter to prevent contact with fenders.

The boom width allows enough space in the tractor hood to make adjustments when parking if not aligned properly.

The mounting frame pins on the mast are rounded to allow easy removal.

The mounting frame pins are also used to hold the parking platforms on the mounts.

The parking stands are stored carefully inside the torque tube. This ensures that the parking stands do not obstruct visibility or restrict lift height by getting caught on objects when using the loader at full height.

The parking stands do not interfere with larger tires at any given tread width.

Steps to hook/unhook the loader

- Dump bucket approximately 40 degrees below level.

- Lower bucket to ground, applying downward pressure. Do not raise tires off ground.

- Engage parking brake or place transmission in PARKING mode and switch off engine.

Parking system elements

Stored parking stands (1)

Stored parking stands (1)

Round mast pin (2)

Round mast pin (2)

1. Parking stands stored in torque tube

2. Round mast pin

Compatibility

Two-wheel drive (2WD) and mechanical front-wheel drive (MFWD) tractors

6E Series Tractors

Universal mount

Universal mount

Universal mount

Features:

- The locking lever is on the left side of the loader to save time when unhooking attachments.

- The locking mechanism is in the carrier, eliminating the need to buy safety catches for each attachment used.

- The carrier is compatible with any competitor attachment that meets ISO standards.

- The carrier is composed of a rigid bottom square tube and a solid top bar, creating a strong structure to reduce twisting if only one hook is mistakenly engaged while connecting an attachment.

- The top bar of the global carrier is cold-coupled for improved wear resistance.

Universal mount options

See universal mount options for more information.

Removable stationary fenders

Removable stationary fender

Removable stationary fender

Features

Stationary fenders are attached to the loader mounting frames and therefore do not rotate when the tractor tires turn.

Stationary fenders offer several key advantages over traditional fenders:

- The turning radius of the tractor is not reduced when a loader is installed.

- Fenders can be used with the tallest tires and a loader at any tread setting.

- Damage to the fenders is reduced as the fender never protrudes from the tractor when turning near fences or walls.

- Fenders can be easily removed to make servicing the tractor easier.

- The height of the fender can be adjusted based on the height of the tire.

- Mud coverage is not compromised.

Stationary fender elements

Fender disassembled (1)

Fender disassembled (1)

Fender mounting point (2)

Fender mounting point (2)

1. Disassembled stationary fender

2. Stationary fender mount

Fender with tractor turned (3)

Fender with tractor turned (3)

Fender with tractor parked (4)

Fender with tractor parked (4)

3. Stationary fender when tractor is turned

4. Stationary fender when tire is parked

Stationary fender options

See stationary fender options for more information.

Mechanical self-leveling (MSL) feature

This improves actual cycle times and reduces operator fatigue as the operator does not have to worry about keeping the bucket in position when raising or lowering the boom.

It is especially useful when handling very fluid materials, round bales, or when using a forklift to reduce or avoid spillage.

Cylinder locking system

This system is designed for operators who:

Change attachments frequently

Want to change implements as quickly as possible

Enjoy the convenience of not having to leave the operator's seat while changing implements

Have hoses that still need to be uncoupled for third-function implements such as grips and hooks for bundles

Cylinder system locking switch

Cylinder system locking switch

Diverter valve

Diverter valve

Boom height sensor

Boom height sensor

Cylinder locking system with pins open

Cylinder locking system with pins open

Cylinder locking system with pins closed

Cylinder locking system with pins closed

Cylinder locking system options

See cylinder locking system options for more information.