960

Variable Round Baler

- Full frame design

- Unloads 3 times faster

- ISOBUS certified

- Wide range of pickups

Features

Full-frame design gives incredible durability

Steel full frame an industry first

Steel full frame an industry first

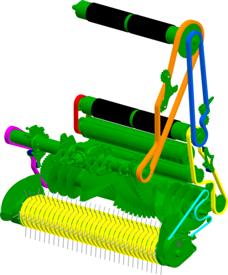

The 900 Series Balers are the first to use a dedicated full frame to hang all the components reulting in greater durability. All loadings, shocks and stress that are encountered are carried by the frame, not any individual component.

Dedicated frame hangs the global baler stress

All components are cradled into the full frame

All components are cradled into the full frame

Due to the exclusive design on the 900 Series, much of the stress is directly transmitted to the full frame giving greater reliability. On a traditional baler, there is no dedicated frame and the baler receives stress from:

- Belt tensioning system

- Bale sides pressure

- Total balers weight

- Potential plugs

- Road transport

- Shocks due to uneven ground

On the 900 Series the bale chamber is isolated from all those constraints giving it a longer life.

Perfectly sized components to fit the function

One part - one function. This simple concept offers a limited weight to the 900 Series Balers, which are not heavier than their main competitors. For example, sidesheets are designed to handle bale side pressure and are not a part of the gate. There is no need to have half of the sidesheet in the bale chamber and the other half in the gate. By disassociating functions, the weight of this heavy part can be cut in half.Less than 5 seconds to unload baler with the fast release system (FRS) boosts productivity

No gate, no wait

FRS - no gate system

FRS - no gate system

A light structure for fast opening

A light structure for fast opening

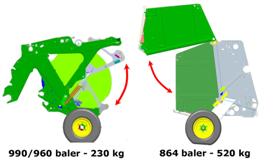

Unloading is unproductive time. With the FRS, the 990 and 960 Balers offer less than 5 seconds unloading time, thereby, reducing bale ejection cycle time, allowing more bales per day. Some competitors require up to 10 more seconds to unload. That means the 900 Series Balers can finish a field one hour earlier than a competitive model based on a 10-hour day.

FRS provides a light structure that opens the chamber quickly and removes belts from the bale. FRS does not require a heavy structure. The FRS gate applies no friction to the side of the bale, allowing the bale to drop quickly unlike competitive machines. There is little stress transmitted to FRS, which can be more than two times lighter than traditional heavy gates. Opening and closing cycles are significantly faster without risk of breakage and with low power requirements.

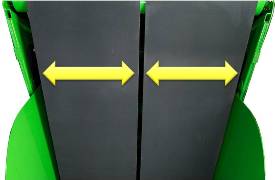

Moving side sheets release the bale faster

Side of the chamber moves

Side of the chamber moves

Moving sidesheets help avoid the bale from getting stuck in the chamber. When the light structure opens, each side of the chamber automatically moves 50 mm. Thus, there is no more contact between the bale and the chamber; the bale is released and quickly falls by its own weight. Even in the worst wet conditions, the unloading process is as efficient as in dry straw.

Unloading ramp gives productivity

Unloading ramp gives smooth/fast bale ejection

Unloading ramp gives smooth/fast bale ejection

Optional unloading ramp gives a smooth and fast bale release without reversing tractor-baler combination. By avoiding this additional reverse move, global baler productivity is increased. With ramp extensions, there is no risk of hitting bales when closing the FRS.

The 900 Series unloading ramp links to the frame by a shock absorber, allowing the bale to be smoothly discharged on the ground. With the additional spring, the ramp can quickly return and be firmly hanged in upper position during baling process and road transport, even on uneven ground.

FRS improves stability in slopes

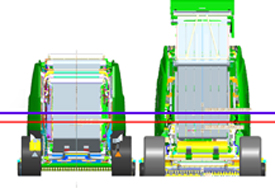

990 center of gravity (red) vs. 864 (blue)

990 center of gravity (red) vs. 864 (blue)

Opening the gate on steep hills with a traditional bale rmay cause instability. The 900 Series offers safe unloading conditions even in hilly fields.

Without a heavy gate to lift during bale release, the center of gravity hardly moves during the opening process. The global height of the baler stays low and allows ample distance from electrical wires.

Rear canvas protection gives security.

Rear canvas avoids direct contact to belts

Rear canvas avoids direct contact to belts

To prevent direct contact between operator and belts when machine is operating, a rear canvas is lowered during the baling process. The protective rear canvas automatically rises during bale unloading.

Advanced net system always gives perfect bale wrapping

Duckbill design feeds the net into the chamber

Net is directly fed between the rolls

Net is directly fed between the rolls

The 900 Series Balers feature a patented high-efficiency net tying system. The new design does not have traditional rubber feeding rollers that can sometime cause net plugs. A duckbill pinches the net that is directly fed between the two front rolls of the bale chamber. The net is caught by the bale and covers the bale perfectly. An exclusive knife and counter knife system ensures an accurate net cut and avoids irregular net tears.

User friendly net system

Easy net loading

Easy net loading

The net system is very efficient and easy to use. A tray is conveniently located on the front of the machine which allows for easy net loading.The front location also makes it easy to visually check the net applying process from the cab. The John Deere system does not require a special tool to feed the duck bill. Two hands and 10 seconds is all it takes to change a net roll.

As with other John Deere variable chamber balers, all parameters (twine/net, number of turns) are quickly set from the display.

In order to optimize productivity, daily maintenance for the 900 Series net tying system is not necessary. It is nearly maintenance free.

COVER-EDGE™ compatibility gives the best bale protection.

Bales perfectly wrapped with COVER-EDGE net

Bales perfectly wrapped with COVER-EDGE net

COVER-EDGE net offers the perfect bale coverage for the 900 Series Balers. This exclusive John Deere net wrap covers the bale perfectly, overlapping the edges 50 mm to 100 mm (1.97 in. to 3.94 in.) to better protect the bale against weather conditions.

The John Deere COVER-EDGE net is recommended for the 900 Series Baler. However, the net tying system is compatible with most net types and brands on the market.

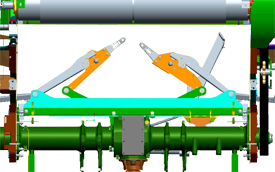

Efficient two arms twine tying system

Two arms with twine cut at the center of the bale

Two arms with twine cut at the center of the bale

For more versatility, a new patented twine tying system has been specially designed for 900 Series Balers. Two arms efficiently feed the twine between the two front rolls in bale chamber. Tying process ends at the center of the bale where twine is cut for a perfect bale finish.

High volume storage limits pit stop

Enough twine and net for a long day

Enough twine and net for a long day

To maximize productivity and reduce downtime, an optional storage box is available for each side of baler. The optional storage boxes hold four net wrap rolls (two in each box). If baler is equipped with the twine tying system, the optional storage boxes hold 10 twine balls (five in each box).

High capacity feeding system grabs the toughest swaths

New pickup design improves capacity and durability

2.2-m (7.22-ft) pickup width to fit the widest windrows

2.2-m (7.22-ft) pickup width to fit the widest windrows

Large diameter stripper and five tine bars

Large diameter stripper and five tine bars

The 900 Series Balers offer a new pickup design with increased capacity. All balers are equipped with a 2.2-m (7.22-ft) wide pickup to match the swaths.

The large-diameter strippers have five tine bars in the pickup instead of four.This increases the capacity by more than 10 percent while reducing rotating speed 12 percent, increasing reliability. Heavy-duty tine bars also provide extended durability to the pickup

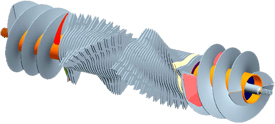

High capacity (HC) rotor for higher productivity

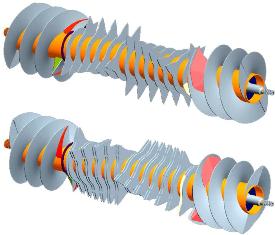

Converging augers are now integrated onto the rotor

Converging augers are now integrated onto the rotor

MaxiCut™ and Rotoflow availability

MaxiCut™ and Rotoflow availability

The 900 Series Balers offer huge feeding capacity due to the HC rotor design. Converging augers are now integrated with the rotor limiting free space between pickup teeth and rotor. Plugging risk is reduced and crop feeding is highly improved. This new design along with a large diameter rotor is particularly efficient in the toughest crops or in difficult conditions, such as crossing windrows.

The simple HC rotor design also reduces the number of moving parts. Loads are distributed all along the rotor increasing overall reliabilitiy.

The 990 and 960 Balers are available with or without precutter, offering space between knives as short as 40 mm (1.57 in.).

|

Rotoflow HC |

MaxiCut HC 13 |

MaxiCut HC 25 |

Number of knives |

0 |

0/13 |

0/12/13/25 |

Knife spacing |

No cutting |

No cutting / 80 mm (3.15 in.) |

No cutting / 80 mm (3.15 in.) / 40 mm (1.57 in.) |

Best use |

Straw, hay |

Silage, hay, straw |

Silage, hay, straw |

New advanced drop floor removes the worst plugs

Drop floor covers rotor full width

Drop floor covers rotor full width

Parallel kinematics avoids narrowing

Parallel kinematics avoids narrowing

Drop floor makes removing plugs easy, even the ones under converging augers. The new design covers all the rotor width, so wherever a plug occurs, the unplugging device allows a 40-mm (1.57-in.) free space. This space is enough to decompress the crops and feed the plug into the baler.

New parallel kinematics provide a consistent 40-mm (1.57-in.) space on the entire drop floor eliminating narrow pinch points like the front-hinged drop floors have.

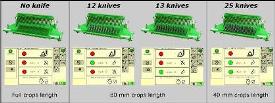

Knives set selection from the monitor

Knives set selection from the monitor

Crop cutting width can easily be adjusted from the cab. A single touch on the screen allows one to engage or disengage all the knives. When equipped with MaxiCut HC 25, half of the knives can also be engaged.

This system offers the use of two different sets of knives for the same cutting width. For example, a set of 12 knives can be used in the morning and a second set of 13 knives can be used in the afternoon. By using two sets of knives, you will always bale with sharp knives, helping to increase productivity and fuel efficiency. This knife selection option allows for longer intervals between sharpening knives.

Put more crop in a bale with the MaxD bale chamber

The widest belts in the market

The widest belts in the market

MaxD bale chamber features wide endless belts to maximize bale density and reduce crops losses.

- The two 573-mm (22.56-in.) width belts increase bale coverage by around 4 percent, thereby reducing possible crop losses between each belt. Wide belts enable a perfect bale shape and grab the crop firmly.

- The endless belts have increased durability at high pressure compared to spliced belts. High tension can be applied for a long time without the risk of breaking a belt, reducing the need for maintenance.

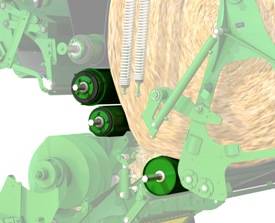

Three powered rolls for easy bale starting and perfect bale shape

Two starter rolls plus one bale chamber roll

Two starter rolls plus one bale chamber roll

MaxDensity (MaxD) bale chamber features three powered rolls to improve versatility and bale quality:

- The three powered rolls facilitate bale starting, especially in wet conditions such as silage. Forage is immediately turning into the chamber and there is no slipping risk even with the heaviest bales.

- Rolls are positioned to give the bale a perfectly round shape, regardless of the bale diameter, the core is ideally centered.

- As belts push crops against rigid steel rolls, high pressureis easily applied, providing high-density bales.

Offset tensioning arms transmit unbelievable density.

Offset density arm gives tension to the belts

Offset density arm gives tension to the belts

The 900 Series offers a new tension system that transmits incredible density to the bales. The heavy-duty offset arm gives tension to the arm and is not involved in belt length compensation. One hundred percent of hydraulic power is involved in belt tensioning.

Movable side sheets: push bale density to max without sticking risk

Movable side sheets = no contact

Movable side sheets = no contact

Baling silage provides tough baling conditions which can cause bales to stick in the chamber. With conventional balers, density may need to be reduced so bales do not stick. The 900 Series Balers have the new MaxD bale chamber that avoids contact between bale sides and baler side sheets when unloading, an industry first. Full density can be set for different crop types. No need to decrease bale density,as the bale unloads within five seconds.

Wider chamber to put more crop in a bale

1.21m width bales = more volume

1.21m width bales = more volume

MaxD bale chamber produces 1.21-m (3.97-ft) width bales, which means the 900 Series provides 3.5 percent more volume than the 800 Series. More volume and more density will no doubt reduce harvest handling and shipping costs. In addition, the maximum bale diameter is increased by 50 mm (1.97 in.), which increases bale volume up to 10 percent compared to the 800 Series Balers. More volume and more density reduce harvest handling and shipping costs.

Simple design allows easy maintenance and setup

Simple driveline gives reliability and reduces maintenance

Crossbeam design

Crossbeam design

Few sprockets and chains for easy maintenance

Few sprockets and chains for easy maintenance

Less maintenance means more time available for baling. That is exactly what contractors and large farms need. The 900 Series Balers benefit from a simple design to reduce downtime. For example, the gearcase is no longer linked to the driveline by yokes. The gearcase is integrated to the frame (crossbeam design) with lubrication free bearings.

Also, fewer sprockets and fewer chains limit wear and potential downtime. Six chains drive all moving parts.

The 900 Series chains are heavy duty, giving up to 40 percent more durability.

Automatic chain lubrication gives simple daily maintenance

High-capacity oil tank reduces refills

High-capacity oil tank reduces refills

Chains are critical components and need a regular and efficient lubrication. The 960 and 990 Balers offer an automatic chain lubrication pump as base equipment. This accurate system allows independent chain lubrication settings. All chains are continuously oiled for better durability, not just during gate opening like some competitors.

For perfect results, use environment friendly John Deere Bio Multiluber oil.

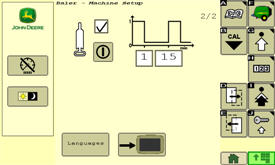

Automatic greasing offers error proof maintenance

Automatic greasing device is easily refilled

Automatic greasing device is easily refilled

Greasing parameters are set from the display

Greasing parameters are set from the display

Hurrying during daily maintenance can cause grease fittings oversight and potential damage. The 960 and 990 Balers offer an optional automatic greasing device. This system provides grease to bearings that require daily greasing.

With ISOBUS technology, greasing parameters are easily and accurately adjusted from the display. Regular greasing gives longer parts durability resulting in better reliability. Grease tank capacity requires refill only once during harvesting season.

If optional automatic greasing device is not chosen, maintenance is facilitated by grease banks grouping the grease fittings.

ISOBUS and tractor-implement automation offer new baling experience

Tractor-Implement Automation simplifies baling experience

A single manual action; system manages the rest

A single manual action; system manages the rest

TIA awards

TIA awards

The optional Tractor-Implement Automation (TIA) makes baling easy. This exclusive system manages most of the baling process and gives the customer the following advantages:

- High baling comfort a single action to bale instead of four.

- Error proof baling - even after 10 working hours, the system does not forget any action; a true advantage for an inexperienced driver.

- Constant bale quality - same diameter bale after bale

- Constant productivity - no reduced efficiency due to operators fatigue.

When used with a John Deere ISOBUS tractor, electric selective control valve (E-SCV), and (IVT™) transmission, the system will be able to:

- Stop the tractor when bale size is reached

- Open the gate

- Close the gate when bale is unloaded

The only action remaining is to forward reverser and manage the steering.

If the John Deere tractor is not equipped with IVT but has E-SCV and ISOBUS, opening and closing can be automated.

A single touch on SCV, brakes, or reverser will disengage the automation. In the same way, automated open/close can be momentarily stopped when unloading in hilly conditions.

Tractor-Implement Automation is an exclusive green on green advantage. This advanced technology option has won awards at SIMA and Agritechnica farm equipment show in Europe, a true cost/value guarantee.

NOTE: to run through fully automated mode, a John Deere Isobus tractor with E-SCV and IVT is required. A baler activation key and a tractor activation key (different) have to be ordered.

ISOBUS certified balers

Plug in and bale with ISOBUS

Plug in and bale with ISOBUS

ISobus certified = compatibility guarantee

ISobus certified = compatibility guarantee

The 990 and 960 Balers offer ISOBUS compatibility as base equipment. The balers have been certified ISOBUS conform by independent DLG organism. This standardized communication not only allows the use of John Deere Greenstar2 1800, 2600, or 2630 Displays, but also the use of other ISOBUS conform competitive monitors.

Adapter harnesses for non-ISOBUS tractors are available.

All ISOBUS display will fit the 900 Series

GreenStar3 2630 fits the most demanding user needs

GreenStar3 2630 fits the most demanding user needs

The 960 and 990 Balers can be ordered without a monitor for customers who already have an ISOBUS display, or for those who search more advanced application (field management). Displays other than John Deere Greenstar2 1800 can be purchased through Ag Management Solutions (AMS) pages.

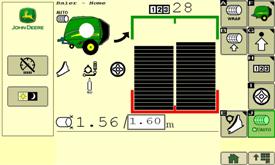

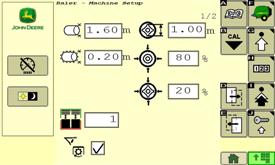

User friendly interface

Main page with simple and clear pictograms

Main page with simple and clear pictograms

Bale or soft core density adjustments

Bale or soft core density adjustments

The Baler interface displays information that is needed. The 900 Series monitors provide all required information:

- Bale shape and diameter

- Drop floor and knives position

- Soft core activation

- Tying process status

- Gate position

- Maintenance status

Adjustments can also be managed from the operators station:

- Bale size and density

- Soft core diameter and density

- Net and twine tying parameters

- Knives selection

- Automated lubrication

- Tractor-Implement Automation status

- Bale counter resets

Greenstar™2 1800 has the ideal display for baling application

Greenstar2 1800 display ordered with the baler

Greenstar2 1800 display ordered with the baler

The 900 Series Balers can be teamed with all ISOBUS certified displays. The Greenstar2 1800 monitor can be ordered with the baler to match traditional baling requirements. When not baling this display can be used for other functions such as guidance and spraying applications when connected to an appropriate receiver and implement.

Related Products

-

348 Small Square Baler

348 Small Square Baler -

450M Round Baler

450M Round Baler -

460M Round Baler

460M Round Baler -

460R Premium Round Baler

460R Premium Round Baler -

560M Round Baler

560M Round Baler -

560R Premium Round Baler

560R Premium Round Baler -

A420R Accumulator

A420R Accumulator -

A520R Accumulator

A520R Accumulator -

C441R Wrapping Chamber Baler

C441R Wrapping Chamber Baler -

C451R Variable Chamber Wrapping Baler

C451R Variable Chamber Wrapping Baler -

F441M Round Baler

F441M Round Baler -

F441R Round Baler

F441R Round Baler -

L331 Large Square Baler

L331 Large Square Baler -

L341 Large Square Baler

L341 Large Square Baler -

V451G Variable Chamber Baler

V451G Variable Chamber Baler -

V451M Variable Chamber Baler

V451M Variable Chamber Baler -

V451R Variable Chamber Baler

V451R Variable Chamber Baler -

V461M Variable Chamber Baler

V461M Variable Chamber Baler -

V461R Variable Chamber Baler

V461R Variable Chamber Baler