Features

Adjustable rigid cutterbar results in efficient feeding

The 600R Header is equipped with the Schumacher Easy Cut II cutting system which provides a best-in-class cutting quality.

Easy Cut II cutterbar

Easy Cut II cutterbar

Feature benefit:

- Non-clog dual-knife guards that fully enclose the sections for positive, clean cutting. High-strength construction provides reliability even when using crop lifters.

- Double-cut sections alternately cut on the upper and lower edges, providing a self-cleaning effect.

- 76-mm (3-in.) sections are bolted, allowing easy replacement in the field.

The Schumacher Easy Cut II cutting system is base on all 600R.

Heavy-duty driveline designed for biggest throughput and best efficiency

The heavy-duty driveline for the auger and cutterbar on the left-hand side of the cutting platform is designed for the biggest throughput and best efficiency and part of the 600R base configuration.

Driveline layout

Driveline layout

Feature benefit:

- Heavy-duty knife drive gearbox

- Slip-clutch protected intake auger protects the combine in case of crop plugging

- Easy to adjust when raising the auger for rape seed harvest

Functionality:

The heavy-duty knife drive gearbox keeps the operator’s head running. The knife gearbox features a cutting speed of 581 rpm for the 616R up to 622R and 62 7rpm for the 625R up to 635R Headers and has a stroke of 89 mm (3.5 in.).

The special-designed gearbox maintains a smooth linear knife motion for reliable vibration-free operation. This gearbox design keeps the header running.

Heavy-duty knife drive gearbox

Heavy-duty knife drive gearbox

Large high-capacity auger provides greater crop material handling

Large high-capacity auger

Large high-capacity auger

Large high-capacity auger

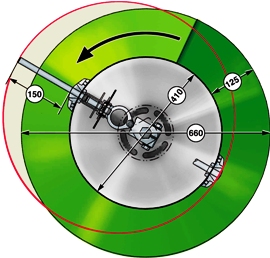

All 600R Series Cutting Platforms feature a large, 660-mm (30.7-in.) auger with deep auger flights to handle large amounts of crop. This design provides a very big area under the auger to aggressively feed large volumes of crop material. The high-capacity auger is available in two different versions, the standard auger and the wear-resistant auger.

Feature benefit:

- All augers are equipped with retractable auger fingers over the full width of the auger

- Auger fingers are designed for quick replacement and mounted with a finger retainer

- Auger finger retainers prevent broken fingers from being moved into the combine, minimizing the potential damage caused by rocks and other obstructions

Full finger auger standard

Full finger auger standard

Functionality:

A unique feature of the 600R Series Headers is the quick adjustability of the auger in two directions: depth and height. This quick adjustment allows the operator to optimize the header for any crop and condition (for example, set the auger up for harvesting rapeseed) for smoothest feeding, an optimal match for the high performance of the John Deere combines.

Depth and height adjustments

Depth and height adjustments

Full-width auger finger

As mentioned above the 600R Series Cutting Platform augers come standard with full-width retractable fingers. That means the operator must always one additional finger between each wrap of auger flights which helps to move tough or green crop faster and creates a more even feeding. The high-capacity auger is easy to maintain and has a great uptime. Each intake finger can be reached easy and comfortable by special designed service doors on the intake auger to keep uptime high and the harvest efficient. The intake auger position is adjustable for maximum versatility.

Full-width auger finger

Full-width auger finger

Unique John Deere fingers

Unique John Deere fingers

The retractable fingers are 16 mm (0.63 in.) in diameter with a reach of 125 mm (4.9 in.). Fingers have a breakaway groove and are secured with a retainer preventing them to enter on the combine. Replacement is fast and easy.

Single-lever multicoupler

A simple, convenient single-lever multicoupler on the left-hand side of the feederhouse allows the operator to connect all hydraulic and electrical header functions, and engages the latch pins in one easy step. The single-lever multicoupler saves time when moving from field to road and vice versa.

Single-lever multicoupler

Single-lever multicoupler

Feature benefit:

- All header connections are done within one single step

- Comfortable to reach at left side of the feederhouse

- Safe and easy operation

Automatic header control (AHC)

600R Front-End Equipment is equipped with two HeaderTrak™ sensors that follow the contour to ensure an even stubble height and minimize the risk of damaging the header in uneven terrain. The HeaderTrak sensors are located on the left and right side of the header.

Control with the lateral-tilt feederhouse

Control with the lateral-tilt feederhouse

Feature benefit:

- Controls the header height in varying terrain

- Includes the lateral tilt control to get clean cut in side hill conditions

- Allows the operator to control the platform ground pressure to have the optimum performance even in down-crop conditions

Functionality:

The automatic-control, programmable header functions provide optimum performance and operator ease and comfort.

The 600R Front-End Equipment is equipped with two HeaderTrak sensors that follow the contour to ensure an even stubble height and minimize the risk of damaging the header in uneven terrain. The HeaderTrak sensors are located on the left and right side of the header.

The 630R Header comes with two HeaderTrak sensors in base. An additional third HeaderTrak sensor is optionally available to ensure maximum performance in uneven terrain.

The 635R Header comes with three HeaderTrak sensors. An additional sensor in the center of the front-end equipment supports the outer sensors in uneven terrain to ensure maximum performance.

HeaderTrak sensors

HeaderTrak sensors

Option Code |

Description |

8790 |

Third platform sensor |

Additional Customer Value:

|

|